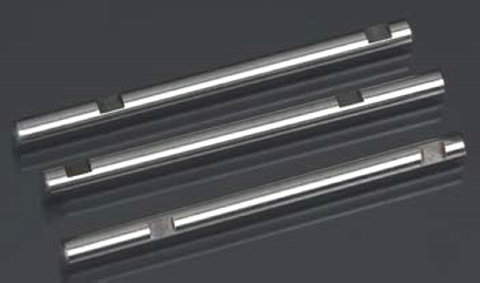

YDTech® manufacturer of tungsten titanium carbide(WTiC) needles,Supplier of tungsten carbide(WC) stick or tungsten rods in china.

What is tungsten carbide?

Typically a Tungsten Carbide Hard Metal can have a hardness value of 1600 HV, whereas mild steel would be in the region of 160 HV a factor of 10 lower. although called a hard metal, Tungsten Carbide is actually a composite material with hard particles of Tungsten Carbide embedded in a softer matrix of metallic Cobalt.

tungsten carbide is often referred to as a Hard Metal due to it’s very high hardness in relation to other metals. qualified for fine turning and half-fine turning when cast iron, chilled cast iron, alloy cast iron, refractory steel, alloy steel, tempered steels and some marks of corrosion-proof high-strength and heat resisting steels and alloys, especially alloys on the basis of the titan, tungsten and molybdenum, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively.

WC-TiC-Co hard alloy also known as tungsten-cobalt alloy or titanium alloy YT. Tungsten carbide, titanium carbide, and metal cobalt alloy composition. by titanium carbide content, can be divided into high-titanium, titanium and low titanium alloy three categories. It tungsten carbide-cobalt alloy than the higher oxidation resistance, hardness and wear resistance, and bending strength, impact toughness has decreased. Mainly used for the machining of steel tools.

Typical Properties of Tungsten Carbide Hard Metals

| ISO | Tungsten Carbide | Cobalt | Hardness | T.R.S | Density | Grain Size | Description | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 513 Class | WC % | Co % | HV 30 | MPa | g/cm3 | µm | Description | |||

| K5 | 93 | 7 | 1850 | 3000 | 14.65 | 0.5 | Ultra fine grained material with very high hardness and wear resistance | |||

| K10 | 94 | 6 | 1690 | 2800 | 14.85 | 1.0 | Fine grain size workhorse grade | |||

| K20 | 92 | 8 | 1710 | 3200 | 14.55 | 0.7 | Fine grain size good hardness and wear resistance with medium toughnes | |||

| Total | 3 WTiC needles,tungsten carbide(WC) stick or tungsten rods | |||||||||

How is Hard Metal or Tungsten Carbide Made?

Tungsten Carbide Hard Metals are primarily produced using a Powder Metallurgy process, whereby the powdered forms of tungsten carbide and cobalt are mixed using ball mills, a binder material is added to hold the powders together during the next stage of the process which is compaction or pressing.

During the compaction processes, hydraulic presses or isostatic presses are used to compact the powders into a shape which approximates the design of the finished product.The sintering process causes the tungsten carbide and cobalt matrix to fuse together to produce a dense “Hard Metal”.

After sintering the material is so hard that it can only be machined by diamond grinding, a specialised form of micro machining that is relatively expensive as it is not possible to remove large amounts of materials by this process.

Applications of Tungsten Carbide and Hard Metals

Tungsten Carbides have a wide range of application in many industry sectors such as metal machining, wear parts for mining and oil industries, metal forming tools, cutting tips for saw blades

Manufacturer and supply of tungsten carbide(WC)

NJTech® always strives to create products with high quality, high technology and high added value. Aim towards a cemented carbide manufacturer of internationally advanced level in respects of cemented carbide. our high quality and good reputation have brought us the trust and support from our customers and cooperators. It has formed a firm, long-term and mutual benefit business relationship among our customers and us.