YDTech™ manufacturers of cobalt nickel beryllium copper(rod,sheet,wire) BeCo alloys; suppliers of beryllium tungsten alloys(rod,sheet,wire) in china.

the high strength of the copper beryllium alloys is attained by age hardening or precipitation hardening. The age or precipitation hardening results from the precipitation of a beryllium containing phase from a supersaturated solid solution of mostly pure copper. The precipitation occurs during the slow cooling of the alloys because the solubility of beryllium in alpha copper decreases with decreasing temperature.

Typically the alloys are rapidly cooled from the annealing treatment, so the beryllium remains in solid solution with the copper. Then the alloy is given a precipitation or age hardening treatment for an hour or more at a temperature between 200 and 460 C. Upon tempering, the beryllium containing phases, called beryllides, precipitate out of solution.

what is beryllium copper(BECO)?

Beryllium Copper(BeCo) alloy is a highly ductile material which can be stamped and formed into very complex shapes with the closest tolerances.

beryllium-copper can be heat treated to harden the alloy into an extremely strong and durable metal. Stamped and formed shapes, such as springs, retain their performance characteristics for long spans of time.

Mechanical properties of beryllium copperBeCo alloys

| grade | diameter | tensile strength | elongation | hardness | Aging Process | |||||

| HRB | HB | |||||||||

| QBe2 | 5-40 | 1000-1380 | 2% | 30-40 | - | 320+/-5°CX3h | ||||

| QBe1.9 | 5-10 | 1200-1500 | 1% | 30-45 | - | |||||

| QBe1.9-0.1 | >10-25 | 1150-1450 | 1% | 35-44 | - | 320+/-5°X3h | ||||

| QBe1.7 | >25 | 1100-1400 | 1% | 34-44 | - | 320+/-5°X3h | ||||

| QBe0.6-2.5 | 5-40 | 690-895 | 6% | - | 92-100 | 480+/-5°X3h | ||||

| QBe0.4-1.8 | 5-40 | 760-965 | 3% | - | 95-102 | 480+/-5°X3h | ||||

| Total | 10 precision BALL(stainless,chrome,carbon) steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

The inclusion of up to 2% of beryllium to copper enables the alloy to retain high electrical conductivity. Equally important, heat-treated beryllium-copper features excellent dimensional stability, fatigue resistance and corrosion resistance. Its strength is greater than ordinary copper alloys and many steels.

Although beryllium-copper is more costly than some metals, the manufacturing process is usually more economical. Die life can be longer and downtimes for sharpening are usually far shorter.

The very significant metalworking advantages, combined with beryllium-copper's superior operating performance qualities, make it the obvious choice for the most demanding applications.

Physical properties of BeCo alloys

| BeCo | QBe2.0 | CuBe10 | CuBe7 | |||||||||

| density20°C | 8.26 g/cm3 | 8.75 g/cm3 | 8.753 | |||||||||

| C.T.E.20-300°C | 1.78x10-5 | 1.76x10-5 | 1.75x10-5 | |||||||||

| specific heat | 0.1Cal/g | 0.1Cal/g | 0.1Cal/g | |||||||||

| conductivity20°C | 22 %IACS | %IACS48 | 38 %IACS | |||||||||

| LME | 130000MPa | 135000MPa | 127000MPa | |||||||||

| TME | 50000MPa | 52500MPa | 49000MPa | |||||||||

| thermal conductivity | 0.2-0.31Cal/cm | 0.40-0.62Cal/cm | 0.40-0.60Cal/cm | |||||||||

| total | 7 beryllium copper(rod,sheet,wire)BeCo alloys | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Typical Application for Beryllium Copper Alloys

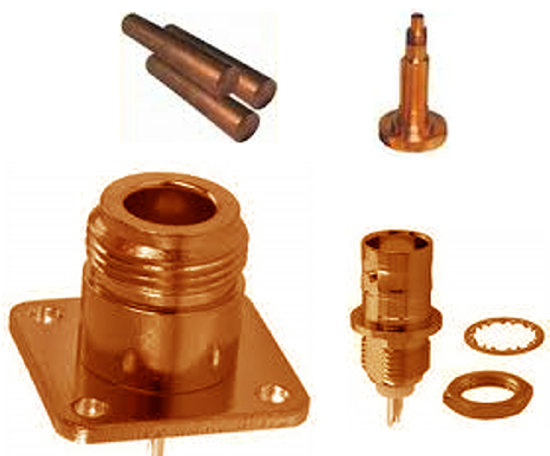

Electrical Industry: Electrical Switch and Relay Blades, Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors, Contact Bridges, Belleville Washers, Navigational Instruments, Clips

Fasteners: Washers, Fasteners, Lock Washers, Retaining Rings, Roll Pins, Screws, Bolts

Industrial: Pumps, Springs, Electrochemical, Shafts, Non Sparking Safety Tools, Flexible Metal Hose, Housings for Instruments, Bearings, Bushings, Valve Seats, Valve Stems, Diaphragms, Springs, Welding Equipment, Rolling Mill Parts, Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Wear Plates on Heavy Equipment, Bellows

The chemical properties of beryllium copper BeCo alloys

| grade | composition | impurities | ||||||||||

| Be | Ni | Co | Ti | Mg | Cu | Al | Fe | Pb | Si | Co | ||

| QBe2 | 1.80-2.1 | 0.20-0.50 | - | - | - | mini | 0.15 | 0.15 | 0.005 | 0.15 | ||

| QBe1.9 | 1.85-2.1 | 0.20-0.40 | - | 0.10-0.25 | - | mini | 0.15 | 0.15 | 0.005 | 0.15 | ||

| QBe1.9-0.1 | 1.85-2.1 | 0.20-0.40 | - | 0.10-0.25 | 0.07-0.13 | mini | 0.15 | 0.15 | 0.005 | 0.15 | ||

| QBe1.7 | 0.60-1.85 | 0.20-0.40 | - | 0.10-0.25 | - | mini | 0.15 | 0.15 | 0.005 | 0.15 | ||

| QBe0.6-2.5 | 0.40-0.70 | - | 2.40-0.70 | - | - | mini | 0.20 | 0.10 | - | 0.20 | ||

| Qbe0.4-1.8 | 0.20-0.60 | - | - | - | - | mini | 0.20 | 0.10 | - | 0.30 | ||

| QBe0.1-1.5 | 0.25-0.50 | - | 1.40-1.70 | - | mini | 0.20 | 0.10 | - | 0.20 | - | ||

| total | 7 beryllium copper(rod,sheet,wire)BeCo alloys | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

The microstructure of the wrought material, after precipitation hardening, contains roughly equiaxed, twinned grains of alpha copper and a dispersion of nickel, cobalt or nickel and cobalt beryllide particles. The grain sizes are relatively fine due the dispersion of the beryllides.

The beryllide particles are roughly spherical and blue gray in color. The beryllides are finer in the wrought material than the cast material because they are broken up during the thermomechanical processing. There is no transformed beta in microstructure of the wrought materials because it is dissolved during thermomechanical processing. The gamma double prime and gamma prime precipitates responsible for the age hardening are too small to be resolved directly with an optical microscope. Etching the sample reveals the dark striations associated with the age hardened precipitates.