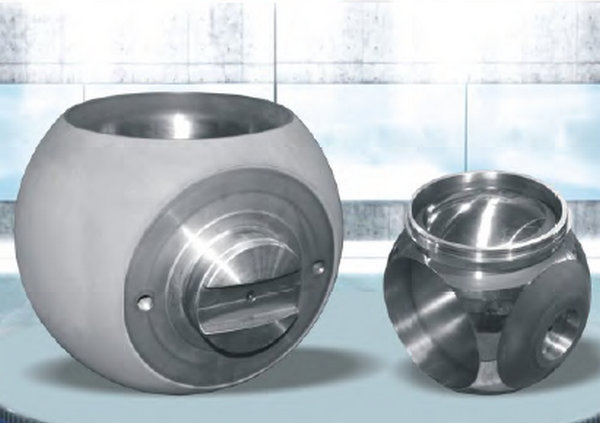

YDTech™ manufacturers of welding valves spheres cores, hollow valve spheres rods pumps, copper, brass half balls valves bodies! supplier of welding valve balls(stainless steel SS304, SS316,chrome) bodies in china!

our ball valve produces all manner of products, with a focus on valve products. in addition, we manufacture other valve parts, pump components, precision machine parts and other products designed to meet customer needs. we also use their advanced equipment to handle materials that are difficult to work with and even coats parts with alloy powder by flame spraying to meet specific customer specifications.

with a forging factory at their disposal, our ball valve efficiently works from raw materials to the finished product. other processes they handle include broaching and chemical treatments such as electropolishing. everything is done in-house, and they work night and day to ensure high quality, short turn-arounds and low costs. we even handle high mix, low volume jobs.

we provide the company with everything from raw materials to finished products particularly ball materials and a number of forged products. we strive for efficiency to cut costs and maximize yield from raw materials. our machining process is particularly efficient with complex pieces requiring multiple steps, and they use their large capacity to shorten delivery times. we can handle precision forging regardless of the material or desired shape.

a trunnion ball valve has additional mechanical anchoring of the ball at the top and the bottom, suitable for larger and higher pressure valves.

a floating ball valve is one where the ball is not held in place by a trunnion. In normal operation, this will cause the ball to float downstream slightly. this causes the seating mechanism to compress under the ball pressing against it. furthermore, in some types, in the event of some force causing the seat mechanism to dissipate , the ball will float all the way to metal body which is designed to seal against the ball providing a somewhat failsafe design.

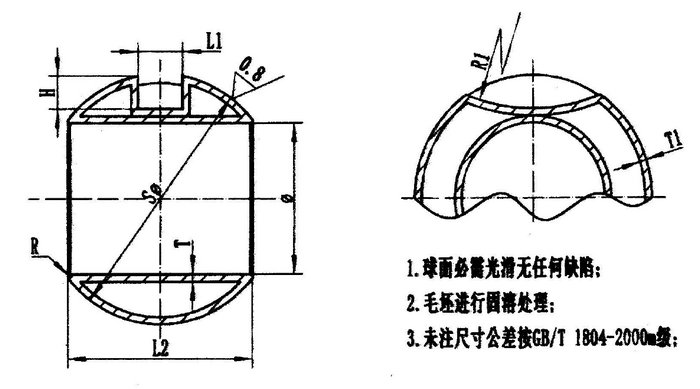

| types | Sφ | φ | R | R1 | H | L1 | L2 | T | T1 |

| DN32 | Sφ53 (+0.10,0) | φ32 | R0.5 | R40 | 7.5 | 10(+0.09,0) | 41 | 3 | 3 |

| DN40 | Sφ66 (+0.12,0) | φ40 | R0.5 | R40 | 7.5 | 12(+0.11,0) | 51 | 3 | 3 |

| DN50 | Sφ80 (+0.12,0) | φ50 | R0.6 | R50 | 9.0 | 14(+0.11,0) | 60 | 3 | 3 |

| DN65 | Sφ 105(+0.14,0) | φ65 | R0.8 | R50 | 12 | 16(+0.11,0) | 80 | 3 | 3 |

| DN80 | Sφ 125(+0.16,0) | φ80 | R1.0 | R50 | 14 | 18(+0.13,0) | 93.2 | 3 | 3.5 |

| DN100 | Sφ155 (+0.16,0) | φ100 | R1.0 | R50 | 15 | 22(+0.13,0) | 115 | 3 | 4 |

| DN125 | Sφ 195(+0.185,0) | φ125 | R1.0 | R50 | 18 | 24(+0.13,0) | 145 | 4 | 5 |

| DN150 | Sφ235 (+0.185,0) | φ150 | R1.0 | R60 | 22 | 28(+0.13,0) | 177 | 4 | 5.5 |

| DN200 | Sφ 301(+0.21,0) | φ200 | R2.0 | R60 | 25 | 32(+0.16,0) | 220 | 5 | 7 |

| DN250 | Sφ 385(+0.22,0) | φ250 | R2.5 | R60 | 28 | 32(+0.16,0) | 288 | 6 | 9 |

| DN300 | Sφ460 (+0.25,0) | φ300 | R3.0 | R75 | 30 | 36(+0.16,0) | 343 | ||

| DN350 | Sφ520 (+0.25,0) | φ350 | R4.0 | R75 | 35 | 40(+0.16,0) | 378 | ||

| DN400 | Sφ600 (+0.25,0) | φ400 | R4.0 | R100 | 40 | 40(+0.16,0) | 439 | ||

| welding hollow valve balls parameters, half spheres,stainless steel SS304, SS316 valve balls, titanium balls | |||||||||

|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- needle rollers

- ceramic balls

- ball bearings

- steel balls

- valve balls

- solid fixed valve spheres

- hollow half valve balls

- welding valve spheres cores

- stainless steel valve balls

- titanium valve balls

- Si3N4 valve balls

- ZrO2 valve balls

- V port valve balls

- 2two or 3three way

- float fixed balls

- coating valve balls

- valve seats