YDTech® manufacturer of large slewing ring TBM(tunnel boring machine) combined bearings! supplier of turntable swing bearings for TBM (tunnel boring machine) in china.

tunnel boring machine, TBM for short, is a special and totally enclosed construction machine for tunneling. During tunnel construction, it's very important to keep from dangers. the most dangerous part is collapse or uplifting of excavation face. Therefore, during working, it's one of key factors to keep steady earth pressure. In other words, very high reliability are needed for screw conveyors and mucking room.

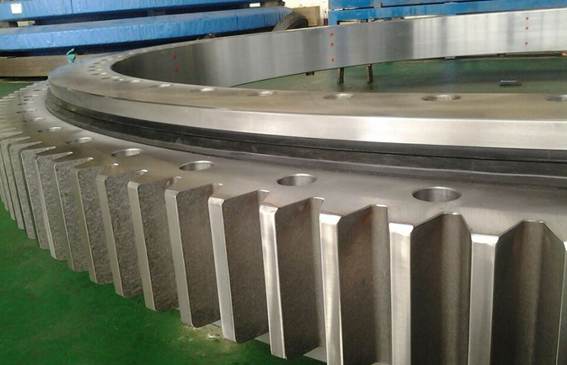

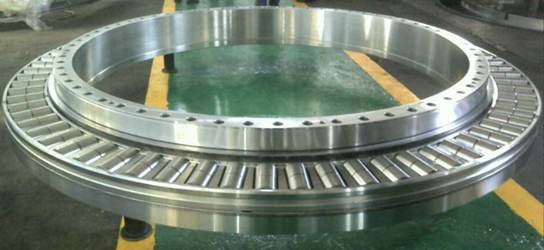

precision slewing ring bearings, engineered to their demanding specifications and delivered on time is a challenge nearly as big as the bearingsthemselves. our experienced engineers specialize in custom designs for hard-rock or soft rock machines, from main cutter heads and segment erectors to screw conveyors. all designs combine performance and technical efficiency with cost effectiveness, and are proven with static and dynamic evaluation.

special sealing and lubrication arrangements are available to further enhance bearing life. We even design the metallic cage separators for the rolling elements to suit each application. after carbonization heat treatment, bearing surface is covered by an indurative carbon layer while the center part is highly flexible.

the construction makes the bearing can take heavy wallop. design and machining is optimized in the profile of the rolling surface. contact stress is covering the surface more even and it's highly improved the ability of anti-peeling from fatigue. It can take heavy loads from both radial and axial directions, with the saving mounting spaces.

good sealing performance is added. under bad working condition, it can avoid invalidation because of water's and feculence's entry to internal part. most of the parts have been already assembled in advance. It's more convenient to assemble it to the equipment. the assembling risk and shutdown time is shortened very much.

- home

- products

- contact

- equipments

- slewing bearings

- single row 4point slew rings

- double row slew bearings

- three row cylindrical roller slewing rings

- crossed roller slewing rings

- balls/rollers combined slew rings

- wind power bearing

- TBM bearings

- rotary table rings

- YRT turntable bearings

- YRTS rotary table rings

- YRTM turntable bearings

- YRTSM rotary table rings

- ZKLDF turntable bearings

- needle roller bearings

- cylindrical roller bearings

- tapered roller bearings

- ball bearings