YDTech® manufacturer of small metal grooved taper pins studs(SS304, SS316, SS440C, SS420)! supplier of mini shafts, grooved pins, needle rollers in china.

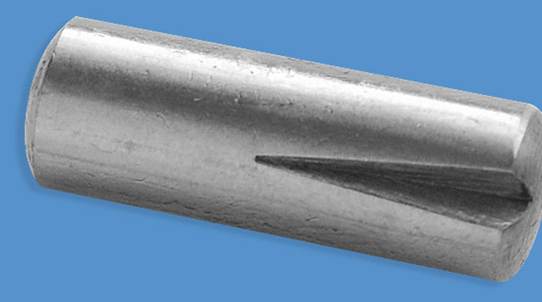

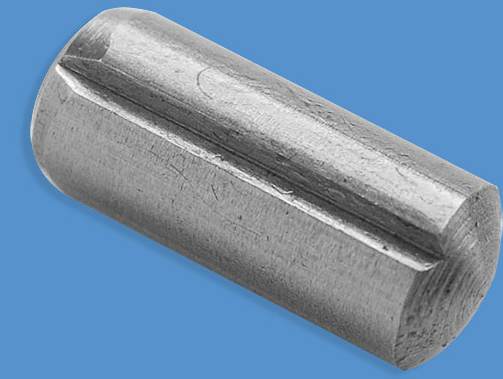

grooved pins are cylindrical pins with grooves or ridges along their length. they are typically used in applications where a positive, non slip connection is required between two parts. grooved pins are commonly used in the construction of machinery, equipment, and tools, where they can be used to secure components in place, align parts, or act as a hinge pin.

grooved pins are used to secure components in place or provide a positive connection between two parts. grooved pins are less elastic but also considerably stronger due to their solid construction.

grooved pins are cylindrical pins with one or more grooves around their circumference. the grooves are designed to allow the pin to compress or flex slightly when it is inserted into a hole, providing a tight fit and holding the components in place.

grooved pins are solid pins with grooves running axially along their surface. the grooves are swaged, which displaces material and increases the diameter of the pins. when the pin is forced into a hole, the grooves close, giving grooved pins more elasticity than dowel pins.

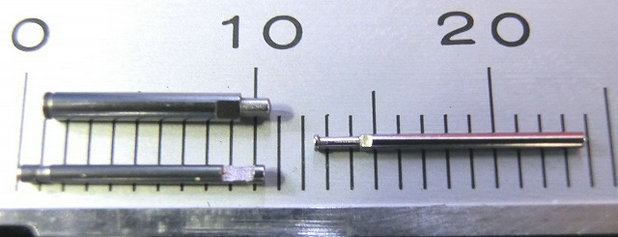

grooved pins are typically made from materials such as steel or stainless steel, and come in a variety of diameters and lengths. they are often used in applications.

grooved pins are cylindrical pins with grooves that are designed to provide a tight fit and hold components in place. while there may be some overlap in the applications for these components, they serve different functions and are designed to meet different requirements.

grooves running part length may be at one end or in the middle, depending on the application.this is a short length of plane pin before the grooves start. since the grooves increase the diameter, this short length before the grooves start allows the pin to align with the hole before it is driven home.

| diameter nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| D(max) | 2.96 | 3.952 | 4.952 | 5.952 | 7.942 | 9.942 | 11.93 | 15.93 | ||

| split(n) nominal | 0.8 | 1 | 1.6 | 2 | ||||||

| split(n) min | 0.86 | 1.06 | 1.66 | 2.06 | ||||||

| split(n) max | 1 | 1.2 | 1.91 | 2.31 | ||||||

| total | 4 grooved dowel pins(taper pins with split) | |||||||||

diameter,C2,kN, tolerance of grooved pins(taper grooved)

| D(max) | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| D(min) | 1.475 | 1.975 | 2.475 | 2.975 | 3.97 | 4.97 | 5.97 | |||

| C2 | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.63 | 0.8 | |||

| kN | 1.6 | 2.84 | 4.4 | 6.4 | 11.3 | 17.6 | 25.4 | |||

| D(max) | 8 | 10 | 12 | 16 | 20 | 25 | - | |||

| D(min) | 7.946 | 9.964 | 11.957 | 15.957 | 19.948 | 24.948 | - | |||

| C2 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | - | |||

| kN | 45.2 | 70.4 | 101.8 | 181 | 283 | 444 | - | |||

| total | 4 grooved dowel pins(taper grooved) | |||||||||

diameter,C2,kN, tolerance of grooved pins(taper grooved)

| D(max) | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| D(min) | 1.475 | 1.975 | 2.475 | 2.975 | 3.97 | 4.97 | 5.97 | |||

| C2 | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.63 | 0.8 | |||

| kN | 1.6 | 2.84 | 4.4 | 6.4 | 11.3 | 17.6 | 25.4 | |||

| D(max) | 8 | 10 | 12 | 16 | 20 | 25 | - | |||

| D(min) | 7.946 | 9.964 | 11.957 | 15.957 | 19.948 | 24.948 | - | |||

| C2 | 1 | 1.2 | 1.6 | 2 | 2.5 | 3 | - | |||

| kN | 45.2 | 70.4 | 101.8 | 181 | 283 | 444 | - | |||

| total | 4 grooved dowel pins(taper grooved) | |||||||||

length tolerance of grooved pins(taper grooved)

| L | min | max | L | min | max | L | min | max | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 7.55 | 8.45 | 10 | 9.55 | 10.45 | 12 | 11.45 | 12.55 | ||

| 14 | 13.55 | 14.45 | 16 | 15.55 | 16.45 | 18 | 17.45 | 18.55 | ||

| 20 | 19.35 | 20.65 | 22 | 21.35 | 22.65 | 24 | 23.35 | 24.65 | ||

| 26 | 25.35 | 26.65 | 28 | 27.35 | 28.65 | 30 | 29.35 | 30.65 | ||

| 32 | 31.2 | 32.8 | 35 | 34.2 | 35.8 | 40 | 39.2 | 40.8 | ||

| 45 | 44.2 | 45.8 | 50 | 49.2 | 50.8 | 55 | 54.05 | 55.95 | ||

| 60 | 59.05 | 60.95 | 65 | 64.05 | 65.95 | 70 | 69.05 | 70.95 | ||

| 75 | 74.05 | 75.95 | 80 | 79.05 | 80.95 | 85 | 83.9 | 86.1 | ||

| 90 | 88.9 | 91.1 | 95 | 93.9 | 96.1 | 100 | 118.9 | 121.1 | ||

| total | 4 grooved dowel pins(taper grooved | |||||||||

- home

- products

- contact

- equipments

- dowel pins

- shear pins

- grooved pins

- precise cylinder

- tapered rollers

- cylindrical pins

- roller rings

- roller gaskets

- roller wedges

- locating pins

- barrel rollers

- crowned ends

- spherical roller

- ceramic rollers

- capillary tubes

- special shape

- PTFE washers

- guide pins

- logarithmic profile

- ultrafine needles

- drive pins

- steel balls

- needle rollers

- cylindrical roller

- standard sizes or stocks