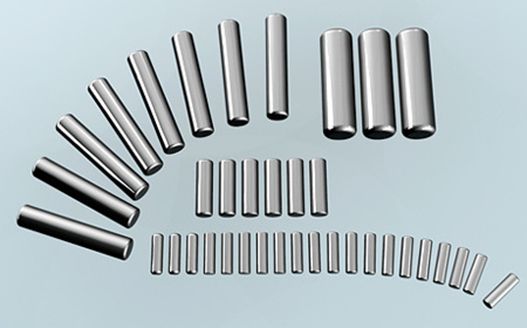

YDTech® manufacturer of small metal locating dowel pins(SS304, SS316, SS440C, SS420)! supplier of miniature shafts locating dowel pins, needle rollers in china.

locating pins are used as precision alignment components in various applications. locating steel pins afford the advantage of maximum hardness combined with corrosion-resisting properties. this hardness, together with precise geometry and fine surface finish, makes them especially useful for bearing where severe environmental conditions may occur.

420C Stainless Steel locating steel pins afford the advantage of maximum hardness combined with corrosion resisting properties. the 420C cylindrical needle rollers has a slightly higher hardness range than 420 stainless steel.

locating steel pins, on the other hand, are typically used as precision alignment components in various applications, such as fixturing, assembly, and machining. locating pins are often made from tool steel or other high-strength materials and have a cylindrical shape with a chamfered tip. the chamfered tip allows for precise alignment of the pin with the mating hole, and the shoulder of the pin ensures that the pin remains in place once inserted.

locating pins 316 stainless steel meet requirements for an unhardened rollers with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing.

locating pins 304 stainless steel meet requirements for an unhardened ball with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing. stainless type 304 cylindrical needle rollers are capable of resisting corrosion by such agents as oxidizing solutions, most organic chemicals, food stuffs and sterilizing solutions. They are moderately resistant to sulfuric acids. Non-magnetic properties available upon request.

locating pins are often made from hardened steel or other high-strength materials and are capable of supporting high loads while maintaining a small profile.

- home

- products

- contact

- equipments

- dowel pins

- shear pins

- grooved pins

- precise cylinder

- tapered rollers

- cylindrical pins

- roller rings

- roller gaskets

- roller wedges

- locating pins

- barrel rollers

- crowned ends

- spherical roller

- ceramic rollers

- capillary tubes

- special shape

- PTFE washers

- guide pins

- logarithmic profile

- ultrafine needles

- drive pins

- steel balls

- needle rollers

- cylindrical roller

- standard sizes or stocks