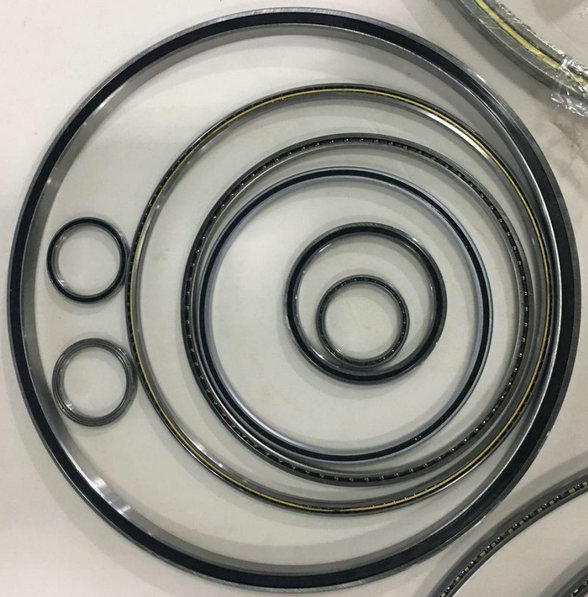

manufacturers of thin-walled equal-section ball rings, UAV power system, drone parts! suppliers of ultra slim equal section ball bearings, industrial robot bearings in china.

thin section bearings are made in radial contact, angular contact, and four point contact. these options, along with several ball and retainer types make for a diverse range of parts even among the limited cross sections of the thin section bearing family.

especially in the case of medical equipment, airborne optical and infrared scanning equipment, and robotics, the space and weight requirements of a system are major factors in the overall design and manufacturing cost. In many cases, the price of a thin section bearing is higher than a standard bearing with a similar bore size, but application and design savings due to reduced space and lower weight decrease the total cost in the application.

the drone can adjust the propeller speed based on the drone’s current position and velocity with other controllers,but without an integral controller, the drone would struggle to maintain a stable hover position.

suppose you have a drone you want to hover in the air at a specific altitude. The drone uses its propellers to generate an upward force that counteracts the force of gravity pulling it down.

imagine the drone as a little flying robot that needs to stay at a certain height in the air, like how a helicopter hovers. to do this, it uses its propellers to create an upward force that balances out the force of gravity pulling it down.

but sometimes, there can be some small problems, can wind might push the drone up or the propellers might not work exactly as expected. This can make a small change in the force so the drone goes slightly higher or lower than the desired height. to fix this, the drone has smart controllers. Three of these controllers are "proportional", “derivative" and "integral”.

the PID (Proportional-Integral-Derivative) control system combines proportional, derivative, and integral controllers to achieve precise and stable drone flight. It effectively counters disturbances and maintains a steady position at the desired height. PID control is widely used in drone flight control and other applications.

| KLFX | KLFX040,KLFX042,KLFX045,KLFX047,KLFX050,KLFX055,KLFX060, KLFX070, KLFX080, KLFX090, KLFX0100, KLFX0110, KLFX0120,KLFX0140, KLFX0160, KLFX0180,KLFX0200 | ||||||||

| KLDX | KLDX040, KLDX042, KLDX045, KLDX047, KLDX050, KLDX055, KLDX060, KLDX065, KLDX070, KLDX075, KLDX080, KLDX090, KLDX0100, KLDX0110, KLDX0120, KLDX0140, KLDX0160, KLDX0180, KLDX0200 | ||||||||

| KLCX | KLCX040, KLCX042, KLCX047, KLCX050, KLCX055, KLCX060, KLCX065, KLCX070, KLCX075, KLCX080, KLCX0100, KLCX0120, KLCX0140, KLCX0160, KLCX0180, KLCX0200 | ||||||||

| KLDC | KLDC040, KLDC042, KLDC047, KLDC050, KLDC055, KLDC060, KLDC065, KLDC070, KLDC075, KLDC080, KLDC090, KLDC100, KLDC110, KLDC120, KLDC140, KLDC180, KLDC200, | ||||||||

| KLCA | KLCA040, KLCA042, KLCA045, KLCA047, KLCA050, KLCA055, KLCA060, KLCA065, KLCA070, KLCA075, KLCA080, KLCA090, KLCA100,KLCA110, KLCA120, KLCA130, KLCA140, KLCA160, KLCA80, KLCA200, | ||||||||

| JLBC | JLBC020, JLBC025, JLBC030, JLBC035, JLBC040, JLBC042, JLBC045, JLBC047, JLBC050, JLBC055, JLBC060, JLBC065 | ||||||||

| JLUC | JLUC040, JLUC042, JLUC045, JLUC047, JLUC50, JLUC055, JLUC060, JLUC065, JLUC070, JLUC075, JLUC080, JLUC090, JLUC100, JLUC110, JLUC120 | ||||||||

| equal section bearings, four point contact ball bearings, thin section deep groove balls, thin angular contact ball bearings | |||||||||

|---|---|---|---|---|---|---|---|---|---|