manufacturers of thin-walled 4 four point contact ball rings, thin wall ball bearings! suppliers of ultra slim 4 four point contact ball bearings in china.

thin-walled four-point contact ball bearings applications: unmanned aerial vehicle , drone PTZ pan-tilt-zoom systems, UAV flight control systems. robotic joints, robotic arms. medical robots, surgical instruments, satellite antennas, radar systems, UAV positioning systems.

thin-walled four-point contact ball bearings are chosen for their ability to combine multiple functions into a compact design, making them an excellent choice for applications where space constraints are a critical consideration. they are available in various sizes and materials to suit different operational requirements.

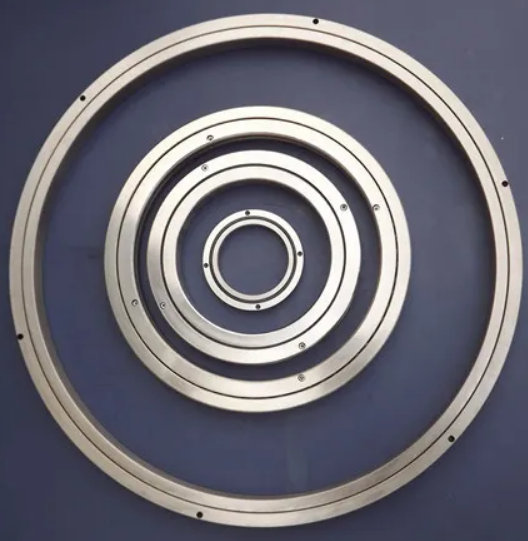

thin-walled 4 four-point contact ball bearings are a specific type of ball bearing designed with a thin cross-section and a four-point contact design. These bearings are primarily used in applications where space is limited, and they are known for their ability to support both radial and axial loads simultaneously. They are commonly used in precision equipment, robotics, and other machinery where compactness and versatility are essential.

thin-walled 4 four-point contact contact ball bearings have two-point contacts, these bearings have four points of contact between the balls and the raceways. This design allows them to handle radial, axial, and moment loads in any direction. thin-walled 4 four-point contact contact ball bearings have a thin cross-section relative to their bore diameter. This design minimizes the overall space required for installation and allows them to fit in tight spaces.

thin section bearings are a family of bearings designed from a limited number of widths and thicknesses, with each cross section manufactured in a wide range of bore diameters. most radial ball bearings are designed so that as the bore size increases, the width and the thickness of the bearing change proportionately. in the case of thin section bearings help reduce total cost in a system by allowing for design efficiency over standard bearing sizes. section bearings the cross section remains the same as the bore diameter increases.

the combination of a large bore diameter in proportion to the small cross section makes these parts appear thin in comparison to standard ball bearings. thin section bearings are made from 52100 chrome steel and 440C stainless steel.

thin section bearings help reduce total cost in a system by allowing for design efficiency over standard bearing sizes. Because thin section bearings have cross sections that don't change as bore sizes increase, there needs to be no change in the space requirements, and little change in the weight of the bearing, even as the diameter of an application increases.

thin-walled 4 four-point contact contact ball bearings are capable of supporting both radial loads and axial loads This makes them suitable for applications where combined loads or varying load directions are encountered. the four-point contact design reduces friction and minimizes heat generation during operation, which can lead to improved efficiency and longer bearing life. thin-walled four-point contact ball bearings are often manufactured to high precision standards, making them suitable for applications where accurate positioning and smooth motion are crucial.