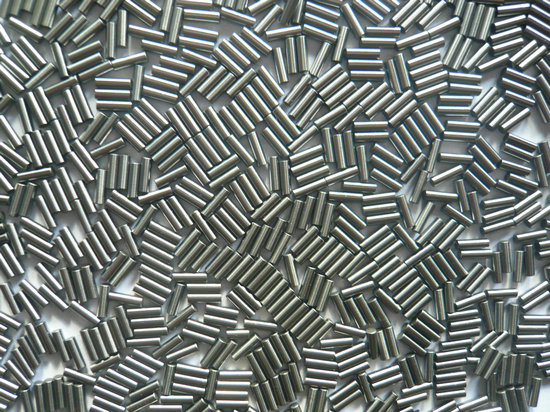

YDTech® manufacturer of precision needle rollers sizes(NRA,NRB)2.5x13.8,2.5x15.8,2.5x17.8,2.5x19.8,2.2x21.8,2.5x23.8 and needle rollers stocks! supplier of 2x17.8,2x19.8,2.5x7.8,2.5x9.8,2.5x11.8, standard needle rollers pins stocks(G2,G3) in china.

The main difference between cylindrical rollers and needle rollers is their shape and size. Cylindrical rollers are cylindrical shaped rolling elements that are relatively thick in diameter, while needle rollers are long and thin cylindrical rollers that are much smaller in diameter than cylindrical rollers.

2x6.8,2x7.8,2x9.8,2x11.8,2x13.8,2x15.8,

2x17.8,2x19.8,2.5x7.8,2.5x9.8,2.5x11.8,

2.5x13.8,2.5x15.8,2.5x17.8,2.5x19.8,2.2x21.8,2.5x23.8

The design of a needle roller bearing typically consists of a thin outer ring, a series of cylindrical rollers, and an inner ring, which may or may not be separable from the outer ring. Needle roller bearings are often used in conjunction with thrust bearings to provide additional support for axial loads. They are available in a variety of configurations, including single-row, double-row, and full complement designs, and can be made from a range of materials, such as steel, brass, or plastic.

Cylindrical rollers are typically used in cylindrical roller bearings, where they are guided by two ribs on either the inner or outer ring of the bearing, and are designed to handle high radial loads.

Needle rollers, on the other hand, are typically used in needle roller bearings, where they are used to reduce friction in applications with limited space, such as in automotive transmissions and aircraft engines.

Overall, the choice between cylindrical rollers and needle rollers depends on the specific requirements of the application, such as the space available, load capacity, and operating conditions.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- needle rollers

- standard sizes needles stocks

- 1mm series

- 2mm series

- 3mm series

- 4mm series

- 5mm series

- 6mm series

- cylindrical rollers

- standard sizes rollers stocks

- 1mm series

- 2mm series

- 3mm series

- 4m~5mm series

- 6mm~7mm series

- 8mm~9mm series

- 10mm~12mm series

- 13mm~17mm seriess

- 18mm~22mm seriess

- 24mm~28mm series

- 30mm~40mm series