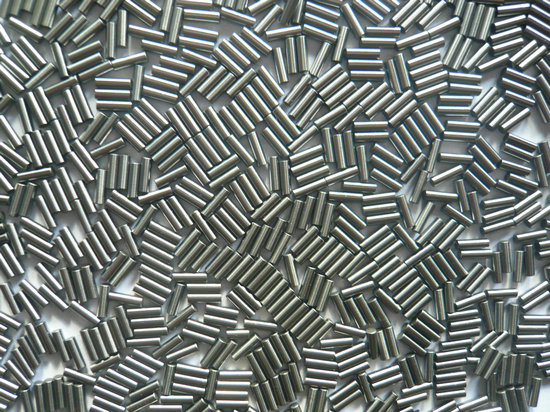

YDTech® manufacturer of precision needle rollers 4x11.8,4x13.8,4x15.8,4x17.8,4x19.8,4x21.8 sizes(NRA,NRB) and needle rollers stocks! supplier of standard cylindrical pins 4x23.8,4x25.8,4x27.8,4x29.8,4x34.8,4x39.8, needle rollers stocks(G2,G3) in china.

we have over 20 years of manufacturing experience of precision rolelrs. we had most stock, delivery time: send to europe, USA, or canada only 3-5 work days

Another important difference is their geometry: cylindrical rollers are typically long and thin in shape, while cylindrical pins have a shorter and thicker design. In addition, cylindrical rollers are typically made of higher-quality materials and manufactured to tight tolerances to ensure smooth operation, while cylindrical pins are more commonly made from lower-grade materials and may not require such tight tolerances.

4x11.8,4x13.8,4x15.8,4x17.8,4x19.8,4x21.8,

4x23.8,4x25.8,4x27.8,4x29.8,4x34.8,4x39.8,

In terms of design, cylindrical rollers are typically longer and thinner in shape, while dowel pins are usually shorter and thicker. Cylindrical rollers are typically made from higher-quality materials and manufactured to tight tolerances to ensure smooth operation, while dowel pins are also made to tight tolerances but may be made from a wider variety of materials, including metals, plastics, and composites.

In summary, while both cylindrical rollers and dowel pins are cylindrical components, they are used for different purposes and have distinct design characteristics. Needle rollers are commonly made from materials that are hardened and ground to improve their strength, durability, and wear resistance. Hardening is the process of heating the material to a high temperature and then rapidly cooling it (quenching) to produce a hard surface layer..

The hardening process for needle rollers typically involves using a high-carbon steel or other alloy steel that is first annealed to reduce internal stresses and improve machinability. The steel is then formed into the shape of the needle roller and heat-treated to a high temperature, typically in the range of 800-900??C (1472-1652??F). The roller is then rapidly quenched in oil or water to produce a hard surface layer with improved wear resistance.

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- needle rollers

- standard sizes needles stocks

- 1mm series

- 2mm series

- 3mm series

- 4mm series

- 5mm series

- 6mm series

- cylindrical rollers

- standard sizes rollers stocks

- 1mm series

- 2mm series

- 3mm series

- 4m~5mm series

- 6mm~7mm series

- 8mm~9mm series

- 10mm~12mm series

- 13mm~17mm seriess

- 18mm~22mm seriess

- 24mm~28mm series

- 30mm~40mm series