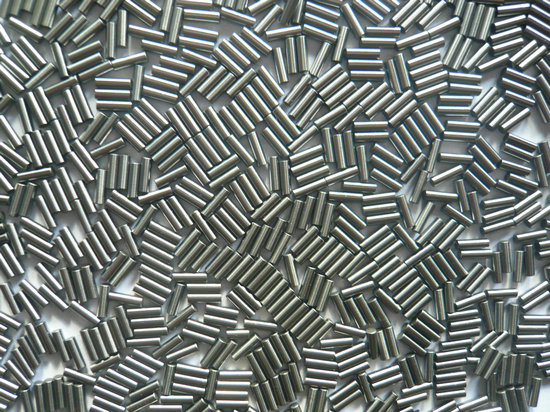

YDTech® manufacturer of 5x27.8, 5x29.8, 5x34.8, 5x39.8, 5x49.8 precision needle rollers sizes(NRA,NRB) and needle rollers stocks! supplier of standard cylindrical pins 5x15.8,5x17.8,5x19.8,5x21.8,5x23.8,5x25.8, needle rollers stocks(G2,G3) in china.

In summary, cylindrical rollers and cylindrical pins are two distinct components with different intended uses and designs A cylindrical roller and a dowel pin are two different types of cylindrical components used in mechanical applications.

After hardening, the needle roller is typically ground to the desired size and surface finish. The resulting needle roller is then able to handle high radial loads in applications where space is limited, such as in automotive transmissions and aircraft engines.

we have over 20 years of manufacturing experience of precision rolelrs. we had most stock, delivery time: send to europe, USA, or canada only 3-5 work days. 5x15.8,5x17.8,5x19.8,5x21.8,5x23.8,5x25.8, 5x27.8, 5x29.8, 5x34.8, 5x39.8, 5x49.8.

In summary, while not all needle rollers need to be hardened, it is a common practice to improve their strength and durability in high-load applications. The hardening process involves heating the material to a high temperature and rapidly quenching it to produce a hard surface layer. Super-precision cylindrical rollers could potentially be used in the manufacture of robot joints, depending on the specific requirements of the application.

Robot joints typically require high precision and accuracy to ensure smooth and repeatable motion. Super-precision cylindrical rollers are designed to provide high precision and low friction in high-load applications, making them a potential option for use in robot joints.

However, the suitability of super-precision cylindrical rollers for robot joints would depend on several factors, including the load capacity, speed, and operating conditions of the joint. Other factors to consider would include the size and shape of the joint, as well as any specific requirements for the roller material, surface finish, or lubrication.

manufacturer and supplier of needle rollers

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- needle rollers

- standard sizes needles stocks

- 1mm series

- 2mm series

- 3mm series

- 4mm series

- 5mm series

- 6mm series

- cylindrical rollers

- standard sizes rollers stocks

- 1mm series

- 2mm series

- 3mm series

- 4m~5mm series

- 6mm~7mm series

- 8mm~9mm series

- 10mm~12mm series

- 13mm~17mm seriess

- 18mm~22mm seriess

- 24mm~28mm series

- 30mm~40mm series