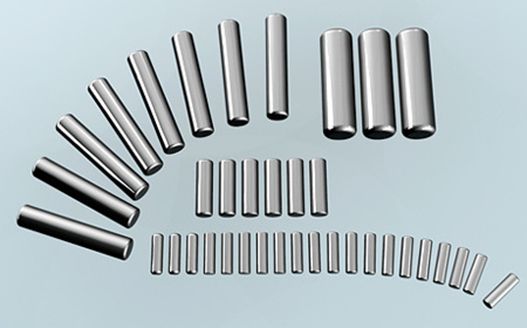

YDTech® MANUFACTURER of hardened needle pins and cylindrical rollers(SS440C,SS420C,SS304,SS303); Supplier of needle rollers(SS440C,SS420C,SS304,SS303) in china.

precision cylindrical needle rollers: stainless steel 440C

AISI type 440-C stainless steel cylindrical needle rollers afford the advantage of maximum hardness combined with corrosion-resisting properties. this hardness, together with precise geometry and fine surface finish, makes them especially useful for bearing where severe environmental conditions may occur.

precision cylindrical needle rollers: stainless steel 420C

AISI Type 420C Stainless Steel cylindrical needle rollers afford the advantage of maximum hardness combined with corrosion resisting properties. the 420C cylindrical needle rollers has a slightly higher hardness range than 420 stainless steel.

precision cylindrical needle rollers: stainless steel 420

AISI type 420 stainless steel cylindrical needle rollers afford the advantage of hardness combined with corrosion-resisting properties. this hardness, together with precise geometry and fine surface finish, makes them especially useful for cylindrical roller bearing.

precision cylindrical needle rollers: stainless steel 316

AISI type 316 stainless steel cylindrical needle rollers meet requirements for an unhardened rollers with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing. type 316 is a low carbon austenitic, chromium-nickel-molybdenum stainless steel with corrosion resistance superior to most other chromium-nickel stainless steels in many types of chemical corrodents, as well as marine atmospheres. applications include, phosphate industry parts, textile finishing equipment, printing equipment, body jewelry and valve industries

precision cylindrical needle rollers: stainless steel 304

AISI type 304 stainless steel cylindrical needle rollers meet requirements for an unhardened ball with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing. stainless type 304 cylindrical needle rollers are capable of resisting corrosion by such agents as oxidizing solutions, most organic chemicals, food stuffs and sterilizing solutions. They are moderately resistant to sulfuric acids. Non-magnetic properties available upon request.

precision cylindrical needle rollers: stainless steel 302

AISI type 302 stainless steel cylindrical needle rollers meet requirements for an unhardened rollers with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing. Stainless type 302 cylindrical needle rollers are capable of resisting corrosion by such agents as oxidizing solutions, most organic chemicals, food stuffs and sterilizing solutions. they are moderately resistant to sulfuric acids. Non-magnetic properties available upon request.

- home

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- bearing steel

- chrome steel

- stainless steel

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- G2G3G5

- special shape

- hardened rollers

- ceramic rollers

- miniature shafts

- Si3N4 rollers

- capillary tubes

- short rollers

- tapered rollers

- dowel pins

- spherical roller

- grooved pins

- ZrO2 rollers