cylindrical rollers are also known for their durability, wear resistance, and reliability, making them an ideal choice for robotic applications that require long service life and high uptime!

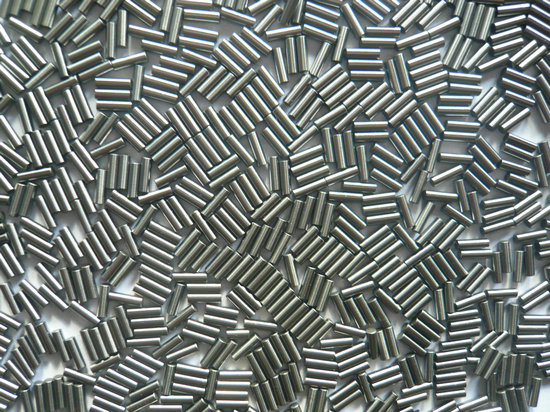

high-precision cylindrical rollers can be used in various types of robots, where precision and accuracy are critical factors for their performance. Cylindrical rollers can be used in robotic applications in several ways, such as in robot joints, linear actuators, and other motion control mechanisms.

Robotic joints often require high-precision cylindrical rollers to achieve smooth and precise motion and positioning. These rollers can be used in both rotary and linear joints to provide low-friction, high load capacity, and precise positioning. High-precision cylindrical rollers can also be used in linear actuators, which convert rotational motion into linear motion, to achieve high-speed, high-precision motion in a compact design.

In addition to their high-precision performance, cylindrical rollers are also known for their durability, wear resistance, and reliability, making them an ideal choice for robotic applications that require long service life and high uptime. However, the selection of the right type of cylindrical roller for a specific robotic application requires careful consideration of several factors, such as load capacity, speed, precision requirements, and environmental conditions, to ensure optimal performance and longevity.

The design of a needle roller bearing typically consists of a thin outer ring, a series of cylindrical rollers, and an inner ring, which may or may not be separable from the outer ring. They are often used in conjunction with thrust bearings to provide additional support for axial loads. Needle roller bearings are commonly used in automotive and aerospace applications, as well as in various types of machinery, such as gearboxes, engines, and pumps. They are available in different configurations, including single-row, double-row, and full complement designs, and can be made from various materials such as steel, brass, or plastic.

manufacturer and supplier of needle rollers

we have over 20 years of manufacturing precision rollers,we had all specifications: diameter from 0.5mm to 60mm. delivery time: send to europe, USA, or canada only 3-5 work days. any inquiry to us immediately!

Email: rollersale@bearing-needles.com

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes