Cylindrical pins, on the other hand, are typically used as alignment components in various applications! needle rollers and cylindrical pins is their function and application!

Needle rollers and cylindrical pins are two different types of components used in mechanical systems, and they have different functions and characteristics.

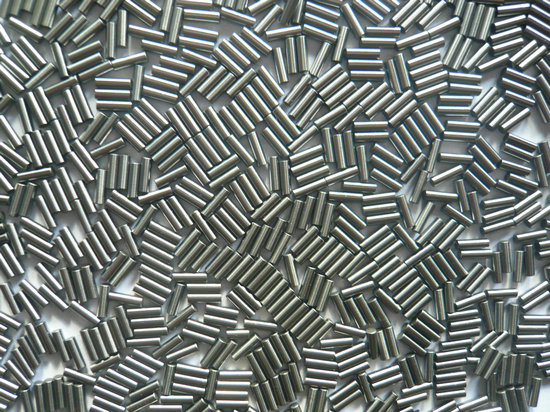

Needle rollers are cylindrical rollers with a long and thin shape, and they are typically used in needle roller bearings to reduce friction and facilitate motion. They are often made from hardened steel or other high-strength materials and are capable of supporting high loads while maintaining a small profile.

In summary, the main difference between needle rollers and cylindrical pins is their function and application. Needle rollers are used to reduce friction and facilitate motion in bearing applications, while cylindrical pins are used as alignment components in various applications. Needle rollers are typically used in high-load bearing applications, while cylindrical pins are used to align and hold parts in place.

Cylindrical pins, on the other hand, are typically used as alignment components in various applications, such as fixturing, assembly, and machining. They have a cylindrical shape with a smooth surface and are often made from materials such as steel, brass, or plastic. Cylindrical pins are used to align two parts or to prevent movement between them by fitting snugly into corresponding holes.

manufacturer and supplier of needle rollers

we have over 20 years of manufacturing precision rollers,we had all specifications: diameter from 0.5mm to 60mm. delivery time: send to europe, USA, or canada only 3-5 work days. any inquiry to us immediately!

Email: rollersale@bearing-needles.com

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes