needle rollers and locating steel pins is their function and application. Needle rollers are used to reduce friction and facilitate motion in bearing applications!

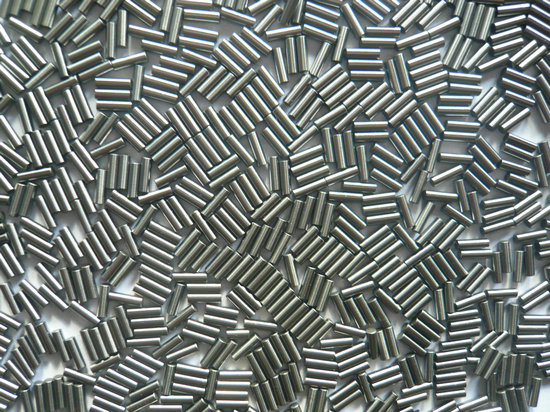

Needle rollers are cylindrical rollers with a long and thin shape, and they are typically used in needle roller bearings to reduce friction and facilitate motion. They are often made from hardened steel or other high-strength materials and are capable of supporting high loads while maintaining a small profile.

the main difference between needle rollers and locating steel pins is their function and application. Needle rollers are used to reduce friction and facilitate motion in bearing applications, while locating steel pins are used as precision alignment components in various applications.

Locating steel pins, on the other hand, are typically used as precision alignment components in various applications, such as fixturing, assembly, and machining. They are often made from tool steel or other high-strength materials and have a cylindrical shape with a chamfered tip. The chamfered tip allows for precise alignment of the pin with the mating hole, and the shoulder of the pin ensures that the pin remains in place once inserted.

small quantities of cylindrical rollers or needle rollers can be manufactured. However, the manufacturing process for cylindrical rollers or needle rollers typically involves several steps, including cutting, grinding, heat treatment, and finishing, which can be time-consuming and costly. As a result, the cost per unit may be higher for small quantities due to the fixed costs of the manufacturing process.

Needle roller bearings are a type of rolling element bearing that use long, thin cylindrical rollers instead of balls to carry and distribute loads. These rollers have a high length-to-diameter ratio and are used to support radial loads, making them ideal for use in various industrial applications where space is limited and high load-carrying capacity is required..

manufacturer and supplier of needle rollers

we have over 20 years of manufacturing precision rollers,we had all specifications: diameter from 0.5mm to 60mm. delivery time: send to europe, USA, or canada only 3-5 work days. any inquiry to us immediately!

Email: rollersale@bearing-needles.com

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes