YDTech® YDTech™ manufacturer of radial combined bearings, axial combined bearings. supplier of balls rollers bearings assemblies,combined needle roller thrust bearings.

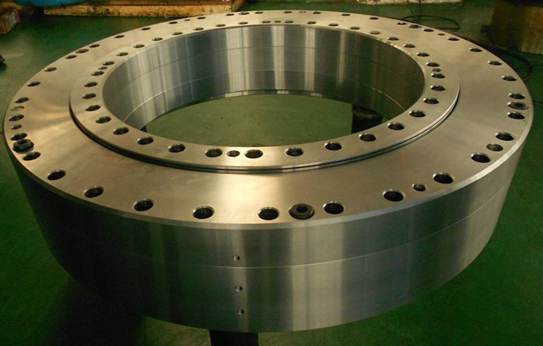

combined bearings are specialized types of bearings that are designed to provide both radial and axial load-carrying capabilities in a single unit. they consist of two or more bearing types, such as ball bearings and roller bearings, combined in a single assembly.

the primary advantage of compound bearings is that they can accommodate both radial and axial loads simultaneously, which can simplify design and reduce the number of components needed in an application. combined are commonly used in applications that require high levels of accuracy and precision.

there are several different types of combined bearings , including angular contact bearings, tapered roller bearings, and deep groove ball bearings, among others. the specific type of bearing used in a combined bearings assembly depends on the specific requirements of the application, including load capacity, speed, and accuracy.

combined needle roller bearings consist of a radial needle roller bearing combined with a thrust bearing and are consequently able to accommodate both radial and axial loads. combined needle roller bearings provide the means to produce locating bearing arrangements where radial space is limited.

combined needle roller bearings consist of a radial needle roller bearing combined with a thrust bearing and are consequently able to take up both radial and axial loads. combined needle roller bearings provide the means to produce locating bearing arrangements in a minimum of radial space. They are particularly useful where the axial loads are too heavy, speeds too high, or lubrication inadequate for simple thrust washers to be suitable, and other types of locating bearing take up too much room.

they are particularly suitable for applications where other types of locating bearings occupy too much space, or where the axial loads are too heavy, the speeds are too high, or the lubricant is inadequate for simple thrust washers.

- home

- products

- contact

- equipments

- cylindrical rollers

- cylindrical roller bearings

- single row roller bearings

- double row roller bearings

- NJ,NU,N,NF,NH,NN

- four row roller bearings

- NU cylindrical roller bearings

- NJ rolling element bearings

- NUP cylindrical roller bearings

- NN rolling element bearings

- NF roller bearings

- NH cylindrical roller bearings

- RNU rolling element bearings

- RN cylindrical roller bearings

- E rolling element bearing

- rolling mill bearings

- thrust cylindrical roller bearings

- needle roller bearings

- tapered roller bearings

- spherical roller bearings

- combined bearings