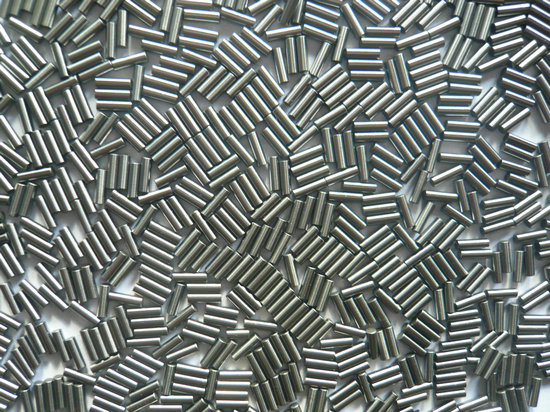

YDTech® manufacturer of precision needle rollers pins bearing steel(GCr15, SUJ2, 100Cr6, SAE52100) and needle roller bearing! supplier of cylindrical rollers or needle rollers bearing steel(GCr15, SUJ2, 100Cr6, SAE52100) in china.

bearing steel cylindrical rollers or needle rollers are cylindrical rollers or needle rollers made from high-quality bearing steel. Bearing steel is a type of high-carbon, high-chromium alloy steel that is designed to provide excellent wear resistance, fatigue resistance, and load-bearing capacity. The most commonly used bearing steel grades for cylindrical rollers or needle rollers include GCr15, SUJ2, 100Cr6, and SAE52100.

bearing steel cylindrical rollers or needle rollers are widely used in various types of rolling element bearings, such as radial ball bearings, cylindrical roller bearings, and tapered roller bearings. These types of bearings are used in many industrial applications, such as automotive, aerospace, machinery, and equipment, where high precision and reliability are critical.

to produce bearing steel cylindrical rollers or needle rollers, the bearing steel is first processed into wire or rod form, which is then cut and formed into the desired shape of the cylindrical roller or needle roller. The rollers are then heat treated to improve their hardness and wear resistance, and the surfaces are typically finished through grinding or polishing to ensure precise dimensions and a smooth surface finish.

bearing steel cylindrical rollers are typically manufactured to tight tolerances and are precision ground or honed to achieve a uniform size and shape. they are also often heat-treated to enhance their strength and durability. bearing steel cylindrical rollers are a high-quality, reliable choice for a wide range of demanding applications where performance and reliability are critical.

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

| specification | mark | C | Si | Mn | S | P | Cr | Mo | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| china(GB) | GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | <0.025 | <0.025 | 1.40-1.65 | - | ||||||

| USA(AISI,UNS) | 52100(G52986) | 0.98-1.10 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.10 | ||||||

| japan (JIS) | SUJ2 | 0.95-1.10 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.08 | ||||||

| germany(DIN/W-Nr) | 100Cr6/w3(1.3505) | 0.95-1.05 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.08 | ||||||

| france NF | 100C6 | 0.95-1.05 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.08 | ||||||

| UK(BS) | 535A99 | 0.95-1.05 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.08 | ||||||

| sweden(SKF) | SKF3 | 0.95-1.05 | 0.15-0.35 | <0.5 | <0.025 | <0.025 | 1.30-1.60 | <0.08 | ||||||

| rolling bearing chrome (axletree) steel cylindrical roller pins,needle rollers | ||||||||||||||

| diameter tolerance | +0/-0.005, +0/-0.003, +0/-0.002, grouping for 0.001mm or 0.0005mm | ||||||||

| length tolerance | +/-0.015, +/-0.01, +0/-0.015, +/-0.005,+0/-0.005 | ||||||||

| radius | R0.03-R0.3 | ||||||||

| parallelism | 0.01, 0.005 | ||||||||

| perpendicularity | 0.01, 0.005 | ||||||||

| circularity | 0.001 | ||||||||

| cylindricity | 0.001 | ||||||||

| roughness | Ra0.1 | ||||||||

| needle rollers, needle roller bearings, miniature pins, needle rollers suppliers, precision shafts | |||||||||

|---|---|---|---|---|---|---|---|---|---|