YDTech® manufacturer of logarithmic curve profile super precision rollers! supplier of overall logarithmic busbar cylindrical roller bearings in china!

needle(cylindrical) rollers=>blended edge rollers,simple radius rollers=>logarithmic profile rollers

about overall logarithmic busbar cylindrical rollers, smallest size: D3*L3, biggest size: D50*L85. stock:D6*L12, D7.5*L11, D8*L8, D9*L9, D10*L10, D10*L11, D10*L18, D11*L11, D12*L14, D14*L15,

through our communication with chstomers, we will get the bearing condition of our customers, then we will use our simulation software to analyze and optimize the best logarithmic curve.

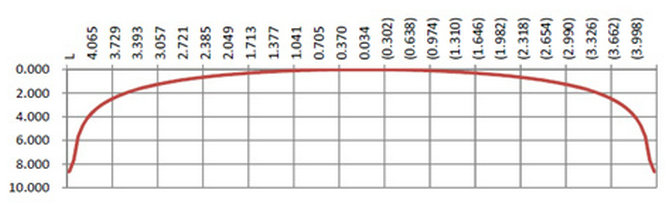

when a bearing roller is in contact with raceways, excessive pressure peaks occur at the ends of the contact rectangles. this is called edge loading. roller and raceway profiles are usually crowned to prevent edge loads. we developed a logarithmic function for a crowned profile. the profile gives an axially uniform pressure distribution.

we developed a logarithmic function as a crowned profile. the profile gives an axially uniform pressure distribution. improved the function for convenience of manufacturing. however, the profile yields edge loading when the roller is tilted. also, the profile allows no straight portion on the roller surface although it is desirable to have a flat region from the viewpoint of machining. in this study, we modified the logarithmic function to exclude edge loading even when the roller is tilted allowing a flat region.

logarithmic profile rollers when a bearing roller is in contact with raceways, excessive pressure peaks occur at the ends of the contact rectangles. they are called edge loading. roller and raceway profiles are usually crowned to prevent edge loads.

according to the stress optimization between the rollers and the raceway, the logarithmic cylindrical rollers will perform a better durabilities, especally on the heacy loading ,dimension stability and slight misalignment bearing application, in the internal testing, the durability will extend to 3.18 times than the straight rollers,the performance will cariate dependend on the raws.

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes