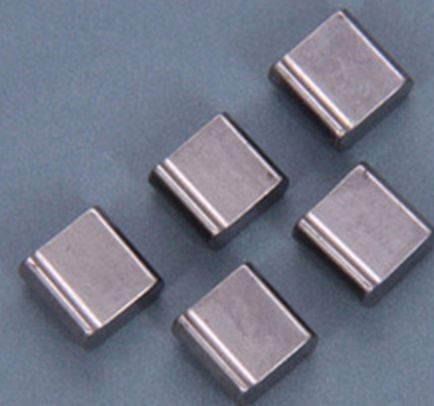

MANUFACTURER of precision wedge(groove) rollers with relieved ends! supplier of pointed ends needle roller or barrel/crowned rollers in china.

the special end rollers are designed primarily for roller bearing applications. end configurations include flat, spherical, and cone shaped. applications for special end rollers include the automotive and industrial markets.\

needle rollers can also be useful in applications where the bearing envelope dimensions need to be kept to a minimum. needle rollers tend to have slightly rounded ends as a stress-relieving feature, improving performance and life characteristics.

the special end rollers is used in bearings where the majority load is in the radial direction. Although mostly cylindrical in shape, some specialist bearings have convex barrel shapes or concave profiles depending on the application type and conditions. special end rollers very populared products by clients, best quality, offer high presison and closed service make receive good sales!

precision needle rollers have multiple uses in a variety of industries including Automotive, truck, farm and construction equipment, two-cycle engines, outboard Engines and consumer durables. Needle rollers are mainly used as bearing rolling Elements to transmit torque and reduce friction. They can also serve as precision shafts or as precision locating pins.

production machines for rollers elements

| instrument name | instrumentation | type | use | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Metallurgical Microscope | Detection of roller Needle heat treatment microstructure | testing equipment | accuracy measurement | |||||||

| Centerless grinding | roller bearings, needle roller machines | production equipment | diameter grinding | |||||||

| Sorting machines | detection of roller, needle roller cylindrical separation | sorting equipment | product separation | |||||||

| Hardness Testing Machines | testing roller bearings, needle hardness of the heat treatment | instrumentation | hardness | |||||||

| total | 4 needle roller bearing needles | |||||||||

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes