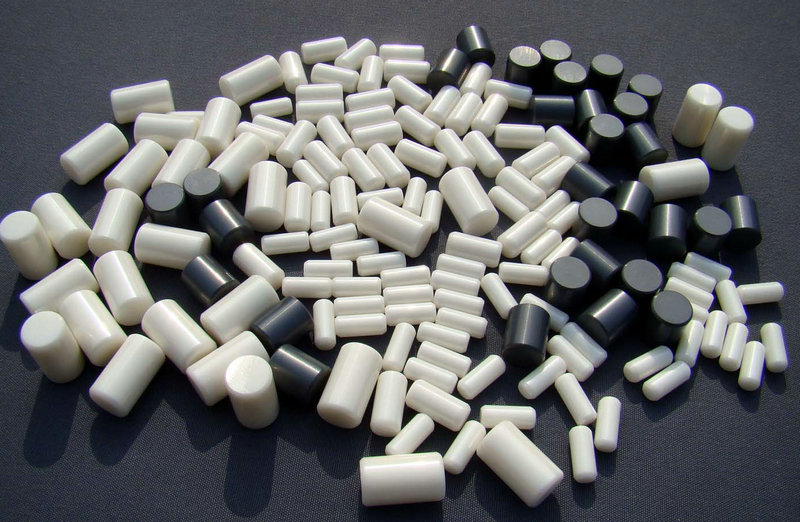

YDTech™ supplier of needle rollers aluminium oxide ceramics(Al2O3)! OEM of ceramic cylindrical pins silicon nitride(Si3N4) or rollers zirconium oxide(ZrO2) in china.

ceramic rollers include silicon nitride(Si3N4) cylindrical rollers, aluminium oxide(Al2O3)needle rollers or zirconium oxide(ZrO2) dowels pins.

silicon nitride ceramic balls deliver unsurpassed performance in critical components such as hybrid bearings. Specified for use in such high-technology industries as aerospace and defense, high-spec ceramic balls feature these advanced characteristics:

silicon nitride (si3n4), just like its close family relation silicon carbide, is one of the toughest technical ceramics available. over the years it has been successfully used in a wide and interesting field of applications ranging from automotive engine components to roller bearings for the most exclusive skateboards . silicon nitride is a hard, solid substance, that can be obtained by direct reaction between silicon and nitrogen at high temperatures. silicon nitride is the main component in silicon nitride ceramics, which have relatively good shock resistance compared to other ceramics.

as a bearing material, silicon nitride is also used extensively for full ceramic bearings and for hybrid ceramic bearings where ceramic balls are successfully used in conjunction with steel races. since silicon nitride ball bearings are harder than metal, contact with the bearing track is reduced resulting in up to 80% less friction and a service life between three to ten times longer than steel. they also afford higher corrosion resistance and allow higher temperature operation. silicon nitride ball bearings can be found in high end automotive bearings, industrial bearings, wind turbines, bicycles, rollerblades and skateboards

aluminium oxide ceramics(al2o3)roller is the the workhorse of the advanced technical ceramic tubes. it has good mechanical and electrical properties, wear resistance and corrosion resistance. it has relatively poor thermal shock resistance.

![]()

aluminium oxide ceramics(al2o3)rollers also have excellent mechanical and anti corrosion properties. calyco can supply hi-performance alumina ceramic rollers in a variety of standard sizes with the flexibility to manufacture to the customers requirements.

refractory ceramic material rollers, they provide excellent corrosion, wear and heat resistance. they improve their hardness when they are subjected to collisions. yttrium doped zirconia oxide, they provide the best properties between ceramic materials in grinding and milling applications. we have a roller made out of this ceramics. this high-strength material exhibits excellent wear and corrosion properties. the material can also be for added strength and edge retention. zirconia exhibits a very low coefficient of friction and is available in mgo or yttria stabilized grades.

- home

- products

- contact

- equipments

- cylindrical roller

- needle rollers

- standard sizes or stocks

- G2G3G5

- bearing steel

- chrome steel

- steel 304

- steel 440C

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- NRB flat ended

- NRA round end

- logarithmic profile crowned

- different ends

- special shape

- hardened rollers

- dowel pins

- miniature shafts

- short rollers

- grooved pins

- capillary tubes