companies of big multirotor UAVs DJ® with radar for mining industry, petroleum! suppliers of huge mining drones DJ® for geological prospecting,oil,gas in china.

mining drones, as survey drones or UAVs (unmanned aerial vehicles) for mining, are specialized unmanned aircraft used in the mining industry for surveying, mapping, and monitoring various aspects of mining operations. mining drones are equipped with sensors and cameras that can capture high resolution imagery, 3D models, and other geospatial data to assist in mine planning, exploration, and environmental monitoring.

mining droness are used for accurate mapping and surveying of mining sites. they can create detailed topographic maps, digital elevation models, and 3D models of the terrain, helping mining companies plan and manage their operations effectively. mining drones are employed in mineral exploration to survey large areas and identify potential mineral deposits. Remote sensing technologies, such as hyperspectral imaging, can help detect minerals and assess the geological composition of the land.

mining drones can monitor and measure the volume of stockpiles of extracted materials, such as ore or waste rock. This information is valuable for inventory management and resource estimation. mining drones are used for safety inspections in mining environments, allowing for the assessment of hazardous or hard-to-reach areas without putting personnel at risk. This includes inspecting high walls, equipment, and infrastructure.

mining drones contribute to environmental monitoring by assessing the impact of mining activities on the surrounding ecosystem. They can monitor vegetation health, track changes in land cover, and identify potential environmental issues. mining drones assist in designing mining pits and monitoring their progress over time. this information helps optimize pit design for efficient extraction and minimize environmental impact.

mining drones can aid in ensuring compliance with environmental regulations and mine planning requirements. the data collected by drones can be used to generate reports for regulatory authorities. mining drones offers several advantages to the mining industry, including increased efficiency, cost savings, and improved safety. By providing accurate and up to date geospatial data, mining companies can make informed decisions, optimize their operations, and minimize the environmental impact of mining activities.

| wheelbase: | 3m | ||||||||

| rotor diameter: | 4.2m | ||||||||

| overall machine height: | 1.1m | ||||||||

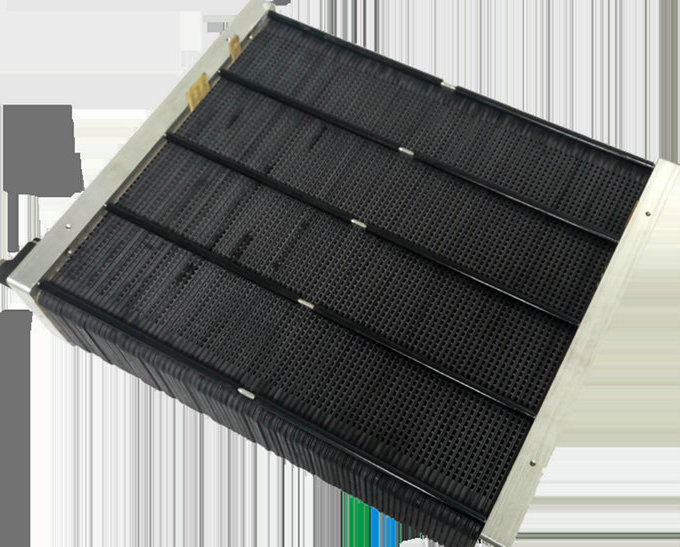

| fuel system: | 3KW open cathode hydrogen fuel cell (8pcs) | ||||||||

| hydrogen storage system: | 12L@35MPa lightweight high-pressure hydrogen storage cylinder (6pcs) | ||||||||

| payload weight: | 30kg | ||||||||

| maximum take-off weight: | 174kg | ||||||||

| empty flight time: | 1.4h | ||||||||

| full load flight time: | 1h | ||||||||

| distributed hydrogen powered UAVs,hydrogen powered drones, best hydrogen fuel cell powered drones,camera drones, mini UAV, adults drones, big UAVsystems, UAV parts. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- UAV

- camera drones

- fixed wing UAV 200

- VTOL aircrafts 220

- hand-throwing fixed-wing UAVs

- quadcopter drones 820

- huge hexacopter UAVs 1550

- big hexacopter UAVs 1100

- drone PCB

- mini drones 180

- PTZ gimbals

- hydrogen powered drones

- drone LiDAR cameras

- FPV drones

- drone hangar

- underwater robotics

- unmanned helicopters

- drone swarms

- aerial photography drones

- agriculture drones

- inspection drones

- police drones

- emergency drones

- logistics drones

- mapping drones

- mining drones