needle rollers are long, thin cylindrical rollers with a high length-to-diameter ratio! grooved pins are cylindrical pins with one or more grooves around their circumference.

needle rollers and grooved pins are both types of cylindrical rollers used in various applications. the primary difference between these two types of rollers is in their design and application.

we have over 20 years of manufacturing experience of precision rolelrs. we had most stock, delivery time: send to europe, USA, or canada only 3-5 work days

grooved pins are cylindrical pins with one or more grooves around their circumference. the grooves are designed to allow the pin to compress or flex slightly when it is inserted into a hole, providing a tight fit and holding the components in place. grooved pins are typically made from materials such as steel or stainless steel, and come in a variety of diameters and lengths. they are often used in applications.

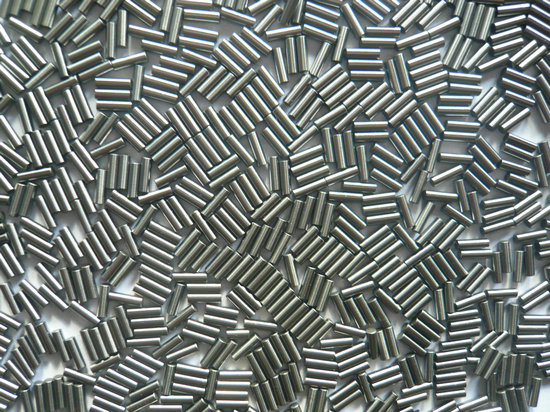

needle rollers are long, thin cylindrical rollers with a high length-to-diameter ratio. they are typically used in applications where space is limited and a high load-carrying capacity is required. needle rollers are commonly used in automotive and industrial applications, such as transmissions, engines, and textile machinery.

on the other hand, grooved pins are cylindrical pins with grooves or ridges along their length. They are typically used in applications where a positive, non-slip connection is required between two parts. Grooved pins are commonly used in the construction of machinery, equipment, and tools, where they can be used to secure components in place, align parts, or act as a hinge pin.

needle rollers are small cylindrical rollers with a length that is typically several times their diameter. they are often used in needle roller bearings, which are used to reduce friction and facilitate motion in various applications. needle rollers are typically made from hardened steel or other high-strength materials, and are capable of supporting high loads while maintaining a small profile.

needle rollers are small cylindrical rollers that are used to reduce friction and support loads, while grooved pins are cylindrical pins with grooves that are designed to provide a tight fit and hold components in place. while there may be some overlap in the applications for these components, they serve different functions and are designed to meet different requirements.

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|