the rollers in a needle roller bearing can vary depending on application. some variations include tapered rollers, crowned rollers

the use of needle rollers in bearings allows for a high load capacity in a small space, making them ideal for applications with limited radial space, such as transmissions, engines, and textile machinery. needle roller bearings can also be used in applications where high accuracy and rigidity are required, such as machine tools and robotics.

we have over 20 years of manufacturing experience of precision rolelrs. we had most stock, delivery time: send to europe, USA, or canada only 3-5 work days

the shape and size of the rollers in a needle roller bearing can vary depending on the specific application and design requirements. some variations include tapered rollers, crowned rollers, and rollers with special surface coatings or treatments to enhance their performance.

In summary, while both cylindrical rollers and dowel pins are cylindrical components, they are used for different purposes and have distinct design characteristics. Needle rollers are commonly made from materials that are hardened and ground to improve their strength, durability, and wear resistance. Hardening is the process of heating the material to a high temperature and then rapidly cooling it (quenching) to produce a hard surface layer..

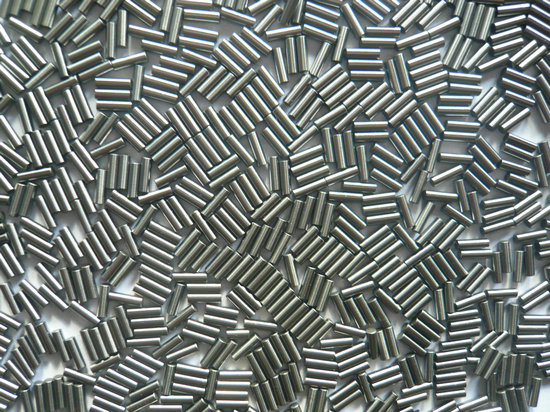

the rollers in a needle roller bearing are cylindrical rollers with a high length to diameter ratio. they are typically made of hardened and ground steel or other materials, and are designed to provide high load-carrying capacity and low friction. the rollers are arranged in a cage or retainer, which holds them in position and maintains the spacing between them.

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|