needle rollers and cylindrical rollers is their size, shape,types of bearings. needle rollers are smaller and thinner,are used in needle roller bearings! cylindrical rollers are larger, uniform shape, are used in cylindrical roller bearings.

the main difference between needle rollers and cylindrical rollers is their size and shape, and the types of bearings in which they are typically used. needle rollers are smaller and thinner, and are typically used in needle roller bearings, while cylindrical rollers are larger and have a more uniform shape, and are typically used in cylindrical roller bearings.

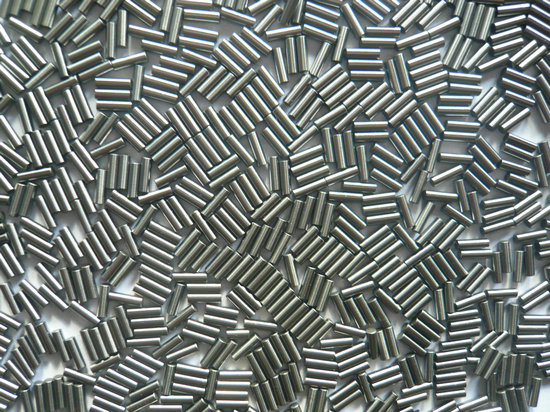

needle rollers and cylindrical rollers are both types of rolling elements used in various mechanical systems, but there are some key differences between these two components.

cylindrical rollers are typically larger in diameter than needle rollers and have a more uniform cylindrical shape. they are often used in cylindrical roller bearings, which are used to support heavy radial loads and moderate axial loads. cylindrical rollers are also typically made from hardened steel or other high-strength materials, and are capable of supporting high loads while maintaining a low profile.

cylindrical rollers are typically used in cylindrical roller bearings, where they are guided by two ribs on either the inner or outer ring of the bearing, and are designed to handle high radial loads.

needle rollers are typically smaller in diameter than cylindrical rollers, and are characterized by their long, thin cylindrical shape. they are often used in needle roller bearings, which are used to reduce friction and facilitate motion in various applications. needle rollers are typically made from hardened steel or other high strength materials, and are capable of supporting high loads while maintaining a small profile.

standard sizes of needle rollers and cylindrical rollers

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|