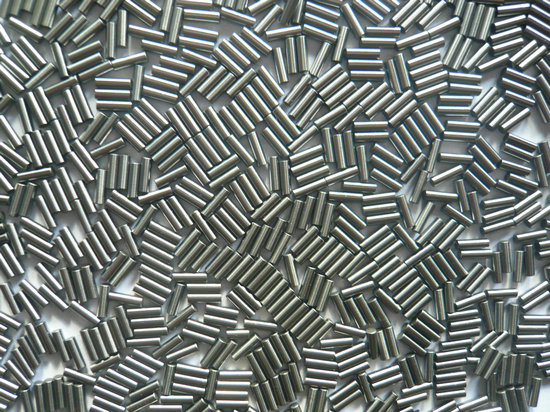

different types of needle rollers: thrust needle rollers, tapered needle rollers, standard needle rollers.

there are several different types of needle rollers, each designed for specific applications and requirements. Here are some of the most common types:

standard needle rollers: these are cylindrical rollers with a small diameter and a high length-to-diameter ratio. they are typically made of hardened and ground steel and are used in a wide range of applications

cage and roller assemblies: these are needle roller bearings that have a cage or retainer that holds the rollers in position. they are used in applications where high-speed rotation is required and where the rollers need to be guided accurately.

drawn cup needle rollers: these rollers have a thin walled outer shell that is drawn over the needle rollers. they are used in applications where a compact and lightweight bearing solution is required, such as in automotive transmissions and air conditioning compressors.

thrust needle rollers: these rollers are designed to handle axial loads and are typically used in applications such as automotive transmissions and machine tool spindles.

tapered needle rollers: these rollers have a conical shape, with a larger diameter at one end than the other. they are used in applications where high radial and axial load capacities are required.

full complement needle rollers: these are needle roller bearings that do not have a cage or retainer. Instead, the rollers are held in position by the raceways of the bearing. they are used in applications where a high load-carrying capacity is required and where the bearing can accommodate slight misalignments.

these are just a few of the many different types of needle rollers available. The specific type of needle roller required for a given application depends on a variety of factors, including load capacity, speed, and operating conditions.

| φ1x5.8 | φ1x6.8 | φ1x7.8 | φ1x9.8 | ||||||

| φ1.5x5.8 | φ1.5x6.8 | φ1.5x7.8 | φ1.5x9.8 | φ1.5x11.8 | φ1.5x13.8 | ||||

| φ2x6.8 | φ2x7.8 | φ2x9.8 | φ2x11.8 | φ2x13.8 | φ2x15.8 | φ2x17.8 | φ2x19.8 | ||

| φ2.5x7.8 | φ2.5x9.8 | φ2.5x11.8 | φ2.5x13.8 | φ2.5x15.8 | φ2.5x17.8 | φ2.5x19.8 | φ2.2x21.8 | ||

| φ2.5x23.8 | |||||||||

| φ3x9.8 | φ3x11.8 | φ3x13.8 | φ3x15.8 | φ3x17.8 | φ3x19.8 | φ3x21.8 | φ3x23.8 | ||

| φ3x25.8 | φ3x27.8 | φ3x29.8 | |||||||

| φ3.5x11.8 | φ3.5x13.8 | φ3.5x15.8 | φ3.5x17.8 | φ3.5x19.8 | φ3.2x21.8 | φ3.5x23.8 | &phi 3.5x25.8 | ||

| φ3.5x27.8 | φ3.5x29.8 | φ3.5x34.8 | |||||||

| φ4x11.8 | φ4x13.8 | φ4x15.8 | φ4x17.8 | φ4x19.8 | φ4x21.8 | φ4x23.8 | φ4x25.8 | ||

| φ4x27.8 | φ4x29.8 | φ4x34.8 | φ4x39.8 | ||||||

| φ5x15.8 | φ5x17.8 | φ5x19.8 | φ5x21.8 | φ5x23.8 | φ5x25.8 | φ5x27.8 | φ5x29.8 | ||

| φ5x34.8 | φ5x39.8 | φ5x49.8 | |||||||

| φ6x17.8 | φ6x19.8 | φ6x21.8 | φ6x23.8 | φ6x25.8 | φ6x27.8 | φ6x29.8 | φ6x34.8 | ||

| φ6x39.8 | φ6x49.8 | φ6x59.8 | |||||||

| loose needle rollers,cylindrical rollers, needle rolling elements, bearing,precision needle rollers | |||||||||

|---|---|---|---|---|---|---|---|---|---|