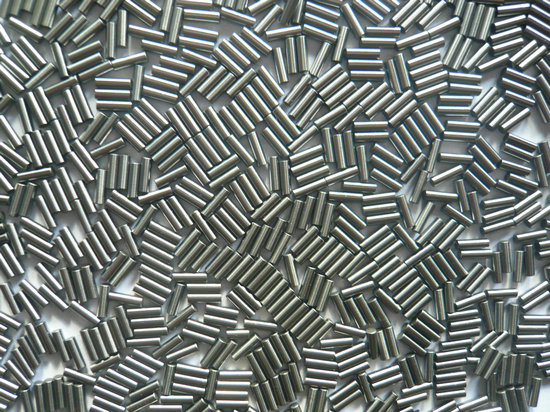

YDTech® manufacturer of hardened stainless steel (SS440C,SS440C) needles dowels pins, cylindrical rollers! supplier of can not hardened stainless steel (SS304,SS316, SS302)needles rollers pins in china.

the specific heat treatment process for cylindrical rollers will depend on the specific grade of steel being used and the desired properties of the rollers for the intended application. It is essential to follow the recommended heat treatment process to ensure that the rollers have the required strength, hardness, and durability for the intended application.

AISI type 440-C stainless steel cylindrical needle rollers afford the advantage of maximum hardness combined with corrosion-resisting properties. this hardness, together with precise geometry and fine surface finish, makes them especially useful for bearing where severe environmental conditions may occur.

AISI type 420 stainless steel cylindrical needle rollers afford the advantage of hardness combined with corrosion-resisting properties. this hardness, together with precise geometry and fine surface finish, makes them especially useful for cylindrical roller bearing

AISI types 316 stainless steel cylindrical needle rollers meet requirements for an unhardened rollers with excellent toughness and resistance to corrosion. corrosion resistance may be increased through annealing. type 316 is a low carbon austenitic, chromium-nickel-molybdenum stainless steel with corrosion resistance superior to most other chromium-nickel stainless steels in many types of chemical corrodents, as well as marine atmospheres.

applications include, phosphate industry parts, needle rollers,crossed rollers, and cylindrical rollers, textile finishing equipment, printing equipment, body jewelry and valve industries

chemical properties for stainless steel needle rollers and cylindrical rollers

| typles | AISI 302 | AISI 304 | AISI 316 | AISI 316L | AISI 420 | AISI 440C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| chrome | 17-19 | 18-20 | 16-18 | 16-18 | 12-14 | 16-18 | ||||||||

| carbon | 0.15 max | 0.08 max | 0.08 max | 0.03 max | 0.15 max | 0.95-1.2 | ||||||||

| nickel | 8-10 | 8-10.5 | 10-14 | 10-14 | - | - | ||||||||

| manganese | 2max | 2 max | 2 max | 2 max | 1 max | max | ||||||||

| silicon | 1max | 1max | 1max | 1 max | 1 max | 1 max | ||||||||

| phosphorous | 0.045 max | 0.045 max | 0.045 max | 0.045 max | 0.045 max | .040 max | ||||||||

| suphur | 0.03 max | 0.03 max | 0.03 max | 0.03 max 0.03 max | 0.03 max | |||||||||

| molybdenum | ... | ... | ... | 2-3 | 2-3 | ...0.75 max | ||||||||

| stainless steel needle rollers,crossed rollers,cylindrical rollers, bearing roller pins, | ||||||||||||||

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

| Dwexceed | Dwto | TSmin | diameter direction TSmin | axis direction TSmin | |||||

|---|---|---|---|---|---|---|---|---|---|

| - | 1 | 0.1 | 0.3 | 0.5 | |||||

| 1 | 1.5 | 0.1 | 0.4 | 0.6 | |||||

| 1.5 | 3 | 0.1 | 0.6 | 0.8 | |||||

| 3 | 6 | 0.1 | 0.9 | 1 | |||||

| needle rollers, needle roller bearings, miniature pins, needle rollers suppliers, precision shafts | |||||||||

V-block measurement for roundness of needle rollers

| angle | wave numbers | ||||||||||

| 3 | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 | 21 | ||

| 90°C | 2 | 2 | - | - | 2 | 2 | - | - | 2 | 2 | |

| 120°C | 1 | 2 | 2 | 1 | - | - | 1 | 2 | 2 | ||

| needle rollers, needle roller bearings, miniature pins, needle rollers suppliers, precision shafts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- needle rollers

- standard sizes or stocks

- NRB flat ended

- NRA round ended

- V chamfering

- logarithmic profile

- special shape

- crowned ended

- ultrafine needles

- short rollers

- manufacturing process

- G2G3G5

- different ends

- hardened chrome steel

- hardened stainless steel

- precision accuracy

- FAQ

- drive pins

- steel balls

- cylindrical roller

- dowel pins