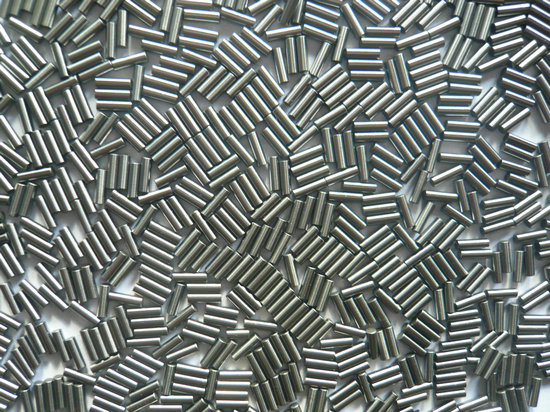

YDTech® manufacturer of precision group hardened steel needles rollers pins! supplier of accuracy group cylindrical rollers or needle rollers in china.

G2, G3, and G5 refer to different levels of dimensional tolerances for needle rollers. These tolerances indicate the allowable deviation from the specified dimensions of the needle roller, such as its diameter or length.

G2 is the tightest tolerance level, indicating a very precise and consistent size and shape of the needle roller. G3 and G5 indicate slightly looser tolerances, with G5 being the least precise of the three.

needle rollers main use is as rolling elements in bearings where they are particularly useful when space is limited and a high radial load is required. They are also useful as locating pins and mini shafts.

the choice of G2, G3, or G5 needle rollers depends on the specific application and the required level of precision. In applications where very precise motion or positioning is required, G2 needle rollers may be preferred. In applications where looser tolerances are acceptable, G3 or G5 may be sufficient.

we have over 20 years of manufacturing experience of precision rolelrs. we had most stock, delivery time: send to europe, USA, or canada only 3-5 work days

.

usually, the material of needle rollers(cylindrical rollers) is chrome steel 52100, then stainless steel: such as 302,304,316,306AL,420,420C,440C etc. then tungsten steel, the newest ceramic material is silicon nitride (si3n4), or zirconium oxide(ZrO2) etc

we are professional manufacture of bearing rollers and cylindrical needle rollers. we produce rollers of diameter 0.5 mm to 60 mm. the rollers could satisfy the request of DIN 5402 G2 rollers.

| diameter tolerance | +0/-0.005, +0/-0.003, +0/-0.002, grouping for 0.001mm or 0.0005mm | ||||||||

| length tolerance | +/-0.015, +/-0.01, +0/-0.015, +/-0.005,+0/-0.005 | ||||||||

| radius | R0.03-R0.3 | ||||||||

| parallelism | 0.01, 0.005 | ||||||||

| perpendicularity | 0.01, 0.005 | ||||||||

| circularity | 0.001 | ||||||||

| cylindricity | 0.001 | ||||||||

| roughness | Ra0.1 | ||||||||

| needle rollers, needle roller bearings, miniature pins, needle rollers suppliers, precision shafts | |||||||||

|---|---|---|---|---|---|---|---|---|---|

chamfer limits of flat ends needle rollers

| Dwexceed | Dwto | TSmin | diameter direction TSmin | axis direction TSmin | |||||

|---|---|---|---|---|---|---|---|---|---|

| - | 1 | 0.1 | 0.3 | 0.5 | |||||

| 1 | 1.5 | 0.1 | 0.4 | 0.6 | |||||

| 1.5 | 3 | 0.1 | 0.6 | 0.8 | |||||

| 3 | 6 | 0.1 | 0.9 | 1 | |||||

| needle rollers, needle roller bearings, miniature pins, needle rollers suppliers, precision shafts | |||||||||

- home

- products

- contact

- equipments

- needle rollers

- standard sizes or stocks

- NRB flat ended

- NRA round ended

- V chamfering

- logarithmic profile

- special shape

- crowned ended

- ultrafine needles

- short rollers

- manufacturing process

- G2G3G5

- different ends

- hardened chrome steel

- hardened stainless steel

- precision accuracy

- FAQ

- drive pins

- steel balls

- cylindrical roller

- dowel pins