YDTech® manufacturers of silicon nitride (Si3N4) pump type precision cylindrical rollers! suppliers of water pump silicon nitride (Si3N4) rollers for automobile in china.

silicon nitride fuel pump rollers offer a more durable alternative in high contact stress applications for light and heavy duty diesel engines. providing excellent mechanical reliability at high speeds and loads, these rollers help automotive manufacturers meet the high pressures required to achieve emission standards.

silicon nitride fuel pump rollers offer a more durable alternative in high contact stress applications for light and heavy duty diesel engines. providing excellent mechanical reliability at high speeds and loads, these rollers help automotive manufacturers meet the high pressures required to achieve emission standards.

silicon nitride is a ceramic material known for its excellent mechanical properties, high temperature resistance, and wear resistance. It's often used in various industrial applications, including automotive components.fuel pump rollers application:fuel pump, diesel oil pump, gasoline pump, motor driven pump, water pump, lubricating pump, power steering pump, brake pump, automobile turning power pump, ethanol fuel pump for automobile, self priming oil pump.

application: precision rail type cylinders, precision rail type cylinders, roller type relay, lift valve groups, mechanical flow valve, pneumatic finger, gripper cylinders, electromagnetic flow valves, precision measuring platform, optical measuring instrument guide, manual displacement platform, electric displacement platform, cross rail table, precision cylinder cylinder, linear bearing rail, slide cylinder, rodless cylinder,

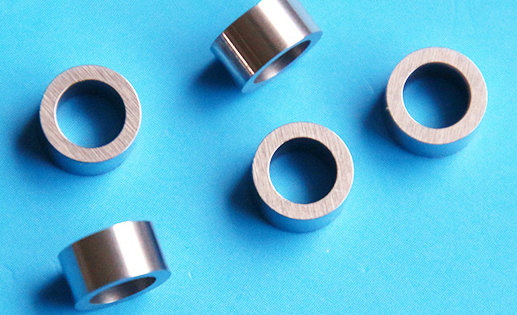

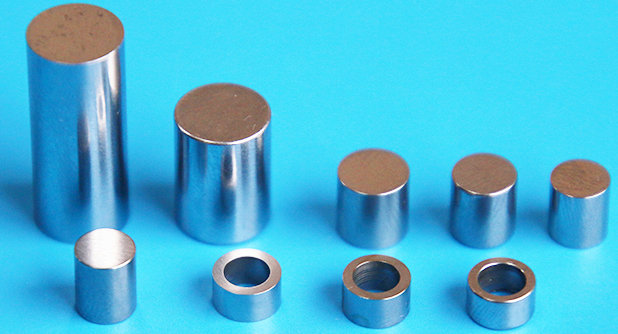

sizes of silicon nitride (Si3N4) and bearing steel fuel pump rollers

| OD | spec OD* Length | ||||||||

| 3.50mm | 3.50*3.50 | ||||||||

| 4.00mmt | 4.0*3.00, 4.0*4.00, 4.0*5.00 | ||||||||

| 5.00 mm | 5.0*4.00, 5.0*5.56, 5.0*6.00, 5.0*7.48 | ||||||||

| 5.50mm | 5.5*3.18, 5.5*5.96, 5.5*6.00, 5.5*6.8 | ||||||||

| 6.00 mm | 6.0*6.00 | ||||||||

| 5.00 mm | 5*6-3 | ||||||||

| 5.5 mm | 5.6*3.39-3, 5.6*3.1*4.0, 5.563*3.145-3.81 | ||||||||

| 6.00 mm | 6*5.99-3.5 | ||||||||

| cylindrical rollers for water pump, lubricating pump,power steering pump, brake pump | |||||||||

|---|---|---|---|---|---|---|---|---|---|

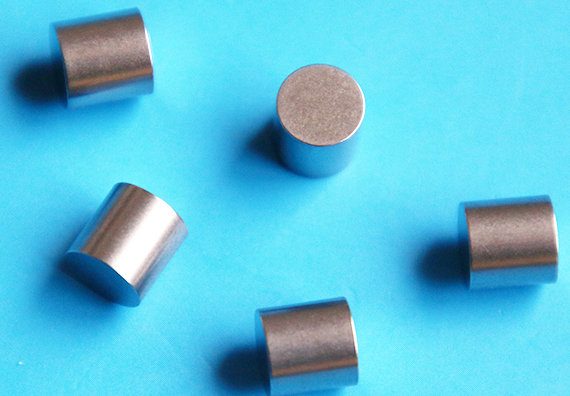

super precision of rollers for fuel pump, oil pump,gasoline pump, motor driven pump

| Item | Spec | ||||||||

| Material: | GCR15, AISI52001, 100CR6 | ||||||||

| Hardness | HRC60-65 | ||||||||

| OD tolerance | 0.005mm | ||||||||

| Length tolerance | 0.001mm (group the length per 0.001mm) | ||||||||

| parallelism | 0.005mm | ||||||||

| perpendicularity | 0.005mm | ||||||||

| Endface runout | 0.005mm | ||||||||

| Roundness | 0.001mm | ||||||||

| Roughness | Ra0.10um | ||||||||

| cylindrical rollers for water pump, lubricating pump,power steering pump, brake pump | |||||||||

|---|---|---|---|---|---|---|---|---|---|

the chief advantage of silicon nitride in high-throughput chemical pumping systems is the outstanding chemical integrity of the material in demanding conditions. Even when operating at high pressures, flow speeds, and temperatures, silicon nitride is inherently resistant to both acidic and alkaline chemicals. this combination of physicochemical properties ensures optimal performance for more aggressive chemistries and slurries.

silicon nitride also vastly exceeds stainless steels when it comes to high-temperature performance. these properties offer a raft of tangible benefits for high-throughput pumping systems in demanding areas of application, which extend far beyond the chemical processing industry. industrial pumps are comprised of numerous integrated components that perform in tandem to induce and control a flow of material. Silicon nitride has been successfully integrated into pumping systems in impellers, seals, shafts, spindles, and nozzles that offer superior performance over conventional materials for extended pumping performance.

the most common pump designs used in the chemicals industry utilize a mechanism that makes direct contact with the process fluid and vapors in a pump headspace. These components are essential in ensuring reliable performance and continuous operation to meet a plant’s bottom line. Stainless steels with elevated chromium contents are often used in rotating shafts and impellers for many positive displacement pumps, as they offer sufficient corrosion resistivity for the most common caustic and acidic chemicals.

heterogeneities in flows can abrade the thin anti-corrosive film of stainless steel causing significant wear and tear over time. High flow speeds and pressures are also typically associated with increased internal operating temperatures which can reduce the performance capabilities and cause costly inefficiencies. Many of these risks can be mitigated by specialist materials like silicon nitride.

silicon nitride (Si3N4) is often used to engineer high-performance pump components for the most demanding industrial sectors: chemical processing, hydrocarbon extraction, oil and gas transport and supply, etc. It is a technical ceramic with outstanding thermomechanical properties and superior anti-corrosive capabilities compared to most engineering alloys. This guarantees an extended service life at higher operating speeds, elevated temperatures, and for liquids and slurries with challenging compositions.