YDTech® manufacturer of drive (driving) pins for CNC face driver centers(chuck, lathe, workholding)! supplier of automatic drive shafts(pins) for CNC mechanical face drive systems in china.

on all face drivers, the center point is secured by a retaining pin engaging the center point keyway. the center point is removed by taking the nose cap and extracting the retaining pins. we only produce drive pins, needle roller pins,custom your drawings not face drivers.we only produce drive pins, needle roller pins,precision hardened parts,etc. custom your drawings or samples. not face driver.

in this state the clamping bolt is clamped over the the power flow, in order to ensure a fixed datumpoint throughout the entire tooling process. the drive disk is floatingly suspended, thus balancing out possible planarity defects of the contact surface of the work piece. the entire surface of the work piece can now be tooled in one single clamping.

to separate the carrier body from the shank assembly, remove the center point, screw plug and compression spring assembly. remove inlet screw hold the face driver in a horizontal position on a bench and insert a brass rod in the bore for the center point. the rod will bottom against drive shank, gentle tapping will separate the carrier body from the shank assembly.

properly applied, a face driver allows you to take very heavy cuts, as much as 1/4" per side. the chisel-edged drive pins bite deep into the end face of the part under pressure from the tailstock. the initial cut, which should be toward the face driver, will help further seat the pins. even under the high torque encountered with aggressive machining, the drive pins will rotate the workpiece without slippage.

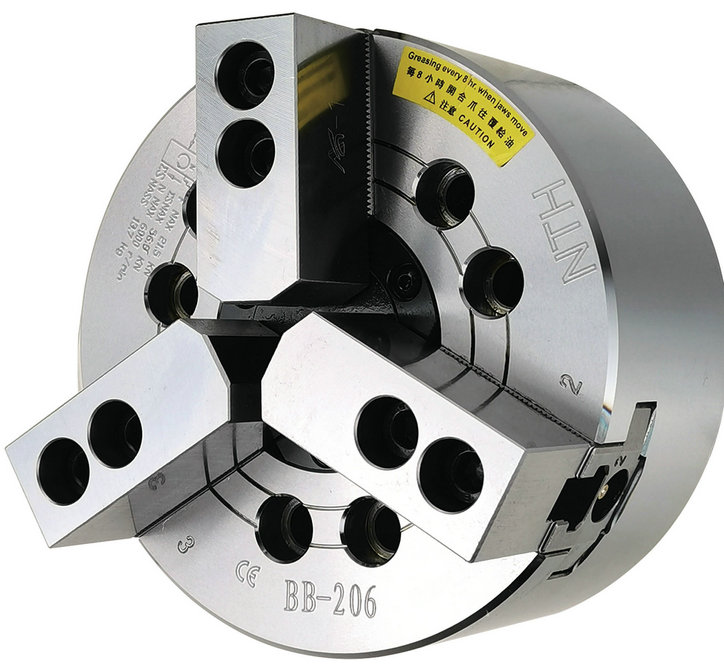

FDT-2 face driver drive pins, lathe face drivers, drive pins, changeable driving pins, drive teeth pins

| drive pins (quantity) | drive pins (diameter) | face drivers (diameter) | face drivers bodies | screws | center pins | FD technologies | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 6 | 160 | 48 | 3 | 22 | FD 2023 | |||||

| 3 | 6 | 160 | 48 | 3 | 22 | FD 2023Z | |||||

| 3 | 6 | 160 | 48 | 3 | 22 | FD 2023F | |||||

| 3 | 8 | 160 | 48 | 3 | 22 | FD 2023D | |||||

| 3 | 8 | 28 | 48 | 3 | 22 | FD 2023D | |||||

| 3 | 8 | 35 | 48 | 3 | 22 | FD 2023HG | |||||

| 3 | 6 | 48 | 42 | 3 | 6 | FD 2023FTY | |||||

| 3 | 6 | 28 | 42 | 3 | 6 | FD 2023JK | |||||

| 3 | 6 | 35 | 42 | 3 | 6 | FD 2023E | |||||

| 3 | 8 | 48 | 48 | 3 | 8 | FD 2023GH | |||||

| 3 | 8 | 28 | 48 | 3 | 8 | FD 2023H | |||||

| 3 | 8 | 35 | 48 | 3 | 8 | FD 2023D | |||||

| 6 | 10 | 48 | 70 | 3 | 14 | FD 2023H | |||||

| 6 | 10 | 35 | 70 | 3 | 18 | FD 2023D | |||||

| 6 | 10 | 48 | 80 | 3 | 14 | FD 2023S | |||||

| 6 | 10 | 35 | 90 | 3 | 24 | FD 2023GF | |||||

| 6 | 15 | 48 | 90 | 3 | 28 | FD 2023F | |||||

| 6 | 15 | 70 | 90 | 3 | 35 | FD 2023JG | |||||

| 6 | 20 | 70 | 132 | 3 | 35 | FD 2023DS | |||||

| 6 | 20 | 70 | 182 | 3 | 35 | FD 2023GG | |||||

| 6 | 20 | 70 | 212 | 6 | 50 | FD 2023JKKL | |||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

the drive pins are "floatingly", thus compensating for variations in work piece, squareness and surface finish. the entire surface of the workpiece can now be finished in one single clamping. we will be glad to design device pins for your work pieces.

center pin: at the center of the face driver is a center pin that holds the workpiece on center line to the other center on the opposite side, which is generally a tailstock, footstock with a live or dead center. a live,dead center is used to center the workpiece and locate its point in the workpiece's center hole. center pins can be changed for different types and sizes of workpieces.they center the workpiece to rotate along the machine's axis and permit the drive pins to engage the workpiece's face. widely accepted in industry today is the spring-loaded center pin design, which includes length positioning from the drive pin or face of the workpiece. fixed-center pins are also available.

the entire surface of the work piece can be tooled and finished by clamping with a maximum of torque transmission. face drivers are mechanical clamping systems which are suited for soft,green as well as hard tooling. face drivers are poweroperated by the thrust of the tailstock. work pieces are clamped centrically using a movable center pin. this way different centerings can be adjusted, thus ensuring a constant datum-point at the end face of work piece.

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes