YDTech™ manufacturer of drive pins of face drivers for CNC machines, lathes on drilling, grinding! supplier of face drivers drive pins on turning, milling, drilling, grindin in china.

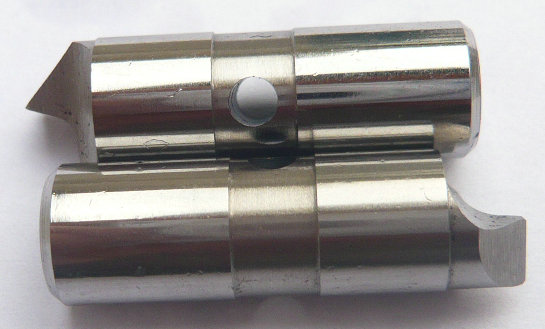

we produce drive pins on the customer's drawings,it's grinding include serrated tip, not lathe processing. act as the teeth of the face driver and bite into the face of the part being machined. Drive pins are replaceable and depending on the size of the driver and the workpiece involved are used in sets of three to ten

driver pins are typically used in a lock's key pins chamber and are designed to interact with the key to allow the plug (cylinder) to turn and unlock the lock. they are not intended to be used as face drivers. we only produce drive pins, needle roller pins,custom your drawings not face drivers.

a face driver is a type of lathe center used to support and drive a workpiece during machining operations. It consists of a rotating center with a set of spring-loaded pins that engage with the face of the workpiece. The face driver is designed to transmit torque to the workpiece and support it radially, while also allowing for axial movement and reducing distortion or deflection.

face drivers are commonly used in turning and grinding applications, particularly for high-precision workpieces that require a high degree of accuracy and surface finish. They are typically used in conjunction with a lathe or grinding machine and can be operated either manually or automatically using a hydraulic or pneumatic system.

other benefits of face drivers are reduced energy costs, as well as less wear and tear on the spindle and on the machines internal components. it takes more energy to spin a large chuck mounted on the machine than it might with a small face driver. mechanical face drivers may also reduce maintenance costs. applying grease when changing drive pins is usually all that is required.

the compatibility of changeable drive pins, drive blade pins for face drivers

| drive pins (quantity) | face drive (diameter) | cneter (diameter) | screw key pins | cneter pins | drive pins (diameter) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 160 | 5 | 3 | 22 | 6 | ||||||

| 3 | 160 | 3 | 3 | 22 | 8 | ||||||

| 3 | 160 | 6 | 3 | 6 | 6 | ||||||

| 3 | 160 | 8 | 3 | 8 | 8 | ||||||

| 6 | 160 | 14 | 3 | 14 | 10 | ||||||

| 6 | 160 | 18 | 3 | 18 | 10 | ||||||

| 6 | 160 | 14 | 3 | 14 | 15 | ||||||

| 6 | 160 | 24 | 3 | 24 | 15 | ||||||

| 6 | 160 | 28 | 3 | 28 | 15 | ||||||

| 6 | 160 | 35 | 3 | 35 | 20 | ||||||

| 6 | 220 | 35 | 3 | 35 | 20 | ||||||

| 6 | 250 | 35 | 3 | 35 | 20 | ||||||

| 6 | 290 | 48 | 6 | 50 | 20 | ||||||

| 6 | 348 | 48 | 6 | 50 | 20 | ||||||

| 6 | 440 | 76 | 6 | 80 | 30 | ||||||

| 6 | 490 | 76 | 6 | 80 | 30 | ||||||

| needle rollers,face driver drive pins, changeable pins, lathe blade pins, driver key pins | |||||||||||

V-block measurement for face driver drive pins, changeable pins, drive blade pins,

| angle | wave numbers | ||||||||||

| 3 | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 | 21 | ||

| 90°C | 2 | 2 | - | - | 2 | 2 | - | - | 2 | 2 | |

| 120°C | 1 | 2 | 2 | 1 | - | - | 1 | 2 | 2 | ||

| needle rollers,face driver drive pins, changeable pins, lathe blade pins, driver key pins | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

FDP-7 standard of drive pins,face drivers, lathe face driver driving pins,sizes of drive pins, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.564 | 2.756 | 0.748 | 0.106 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.828 | 0.145 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.866 | 0.165 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.906 | 0.186 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.945 | 0.205 | FDP 2023 | |||||||

| 0.564 | 2.756 | 0.984 | 0.224 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.024 | 0.244 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.063 | 0.264 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.102 | 0.288 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.148 | 0.308 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.181 | 0.323 | FDP 2023 | |||||||

| 0.564 | 2.756 | 1.417 | 0.487 | FDP 2023 | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

the face driver can help improve machining accuracy, reduce setup time, and increase productivity by allowing for faster and more efficient machining operations. there are two factors to consider when choosing driving pins: pin direction and driving diameter. both are stated in the second and third columns of this table. when choosing a center point make sure the center hole diameter of your workpiece falls within the required range in this table.

with face driver, the entire workpiece is exposed for machining. therefore, you are able to machine the entire length of the workpiece in one operation. the elimination of a setup in the production process results in increased accuracy and efficiency. furthermore, the single axis reference point established by the center point of the face driver allows for a higher concentricity.

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes