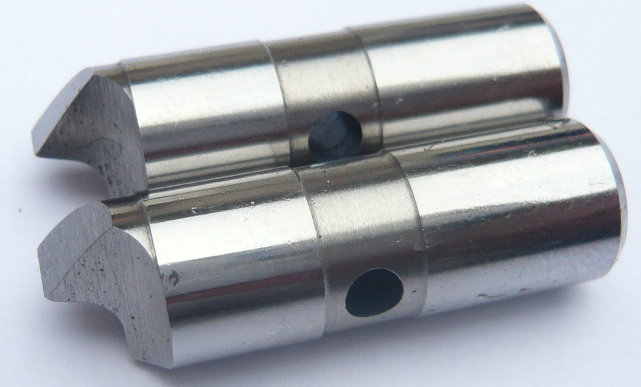

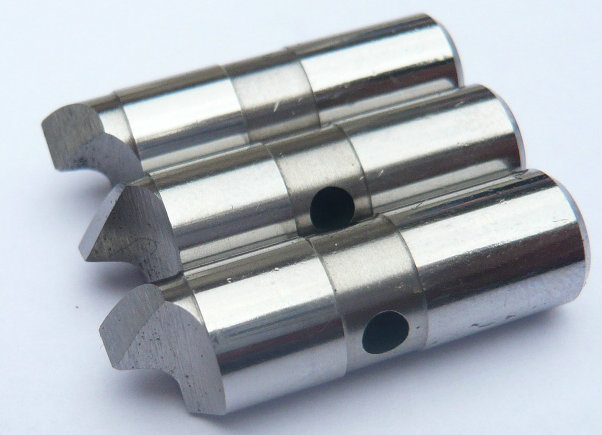

YDTech® manufacturer of center (anchors) pins on face drivers for milling (grinding, lathes) machines! supplier of drive grip pins for face driver systems on lathes, live (dead) chucks in china.

the tailstock force pushes the work piece against the fixed center pin of the face driver. the drive pins are activated by the clamping cylinder mounted into the machine.we only produce drive pins, needle roller pins,custom your drawings or samples, not face drivers.

drive pin for torque transmission onto work piece for hard tooling. for higher friction coefficient and higher tool life of drive pin

for maximum stability and run-out requirements the center pins are produced with narrow tolerances and are fixed safely via set screw and plane surface inside the face driver. due to the accurate assembly between center pin and head of face.

even parts with spherical ends or irregular shapes can be clamped securely with face drivers. these special applications require custom designed pins and centers points matched specifically to the application. face drivers are used in many between center operations, such as hobbing, milling, shaping, grinding, gear cutting, spline milling, facing and turning. standard face drivers are available with driving diameters from 0.28" to 5.74"; suitable for clamping and driving parts from 0.40" to 11.48" in diameter. special drivers, drive pins and center points can be designed for your specific application.

the application must have a machine that can deliver sufficient tailstock force to hold the workpiece. however, force depends on the type of workpiece being turned, the material it is made from, the number of drive pins used in the face driver and what type of operation is being performed. generally, most machines have enough tailstock force for a mechanical face driver.

FDP-3 standard of drive pins,face drivers, lathe face driver driving pins,sizes of drive pins, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.564 | 2.756 | 0.591 | 0.083 | FDPT 2023S | |||||||

| 0.564 | 2.756 | 0.748 | 0.106 | FDPT 2023D | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DD | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DG | |||||||

| 0.564 | 2.756 | 0.827 | 0.146 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.866 | 0.165 | FDPT 2023CV | |||||||

| 0.564 | 2.756 | 0.906 | 0.185 | FDPT 2023FC | |||||||

| 0.564 | 2.756 | 0.946 | 0.205 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.985 | 0.224 | FDPT 2023BNN | |||||||

| 0.564 | 2.756 | 1.025 | 0.244 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.063 | 0.264 | FDPT 2023VV | |||||||

| 0.564 | 2.756 | 1.102 | 0.283 | FDPT 2023F | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VT | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VF | |||||||

| 0.564 | 2.756 | 1.222 | 0.343 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.232 | 0.363 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.417 | 0.441 | FDPT 2023H | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

the face driver product line consists of 7 hydraulic and 10 mechanical designs. this wide range of models offers a large degree of versatility for large parts, such as large rolls, motor shafts and crankshafts; for small parts, such as valve stems, ball studs and automatic transmission shafts; for rough castings and forgings, such as automotive gears.

when using multiple cutting tools, the tool slide feeding toward the headstock should be engaged first. this will firmly embed the drive pins in the workpiece. the distance from the driving face to the headstock will remain identical for all parts within +/-0.002 when constant tailstock force is applied.

other applications, such as hard turning, grinding, gear hobbing and milling, also lend themselves to face driving. for example, gear hob clearance can be an issue for many types of workholding, but with the correctly specified and implemented face driver, this application can be very successful. spring-loaded center pins using a drive disk work well for hobbing. the drive disk can be quickly changed for sharpening or replacement because it is easy to remove.

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes