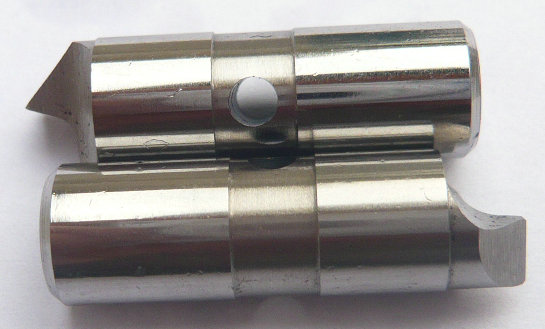

YDTech® face driver components: face driver bodies, driving pins, centre point,wedge lever assemblies,driving pin support washers, driving pin retaining screws.

we only produce drive pins, needle roller pins,custom your drawings not face drivers. Face driver is such a wonderful product for shaft turning. It helps in machining complete shaft in one single setup.This system is more robust and helps in applying great machining parameters.If all is ensured run the machine with the best parameters you can. we only produce drive pins, needle roller pins,precision hardened parts,etc. custom your drawings or samples. not face driver.

face drivers are the upgrade product to instead the traditional lathe clamping apparatuses such as lathe dog and it can stir the dishes and the like on the lathe, it is used to chuck the axis class components which the both ends have the centre bores, face driver is the new generation of machine tool accessories which rapidly rises to the year internationally.

traditional jigs have to clamp the work-piece outer annulus while face driver do not need have to. face driver depends on the jaw to actuate the work-piece the end faces and making it revolving along with the main shafts of lathes. once chucked, the face driver can process the work-piece span. It do not have to turn around to chuck, so can save at least time of above to chuck the non-cutting time.

the equal-diameter do nott exist so-called meets the knife problem, and the precision of each related surface mutual position is advanced after the processing between the work-piece. clamp force is free from the influences of rotational speed of the main shafts, especially adapting the request of high speed turning.

This type of face driver has limitation related to cutting parameters due to less thrust But simple in use and economical. In this case the component is held between centers and thrust is applied to the shaft from tail stock. Face driver on the spindle side will have spring loaded center and floating type driving disc fitted with driving pins which helps in proper biting of pins on to the component face. Float in system helps in any error on the perpendicularity between driving face and center.

FDT-6 face driver drive pins, lathe face drivers, drive pins, changeable driving pins, drive teeth pins

| drive pins (diameter) | drive pins (distance1) | drive pins (distance2) | drive pins (distance3) | drive pins (tooth width1) | drive pins (tooth width2) | drive pins (tooth width3) | FD technologies | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 11 | 17 | 1.5 | 3 | 6 | FD 2023A | ||||

| 8 | 6 | 11 | 19 | 1.5 | 4 | 8 | FD 2023DS | ||||

| 6 | 11 | 14 | 22 | 1.5 | 4 | 8 | FD 2023D | ||||

| 8 | 13 | 18 | 26 | 1.5 | 4 | 8 | FD 2023EE | ||||

| 11 | 14 | 31 | 20 | 1.5 | 3 | 6 | FD 2023DX | ||||

| 26 | 31 | 36 | 44 | 5 | 7.5 | 10 | FD 2023X | ||||

| 15 | 39 | 49 | 59 | 5 | 10 | 15 | FD 2023D | ||||

| 15 | 49 | 59 | 69 | 5 | 10 | 15 | FD 2023XF | ||||

| 20 | 69 | 89 | 99 | 5 | 10 | 15 | FD 2023FR | ||||

| 20 | 110 | 120 | 140 | 5 | 12.5 | 20 | FD 2023T | ||||

| 20 | 140 | 150 | 170 | 5 | 12.5 | 20 | FD 2023V | ||||

| 30 | 320 | 340 | 360 | 5 | 12.5 | 20 | FD 2023VG | ||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

when the work-piece end surface has time the big position error to the middle line, it can still guarantee work-piece reliably clamped. the synthesis processing efficiency is high, and labor intensity of operators can be reduced remarkably.

some face driver can achieve loading and unloading in the condition of ceaselessly working, not only can further enhance the production efficiency, but also in favor of reducing the energy consumption, prolong the life span of equipments. application of face drivers: widely applied in the small and middle-medium lathes and the domestic. lathes, is suitable specially for the CNC lathes and the hydraulic pressure lathes.

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes