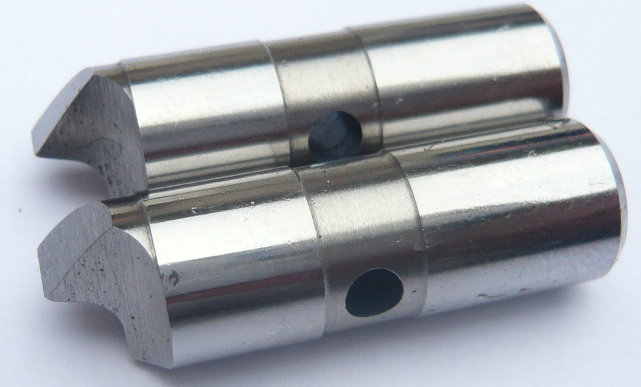

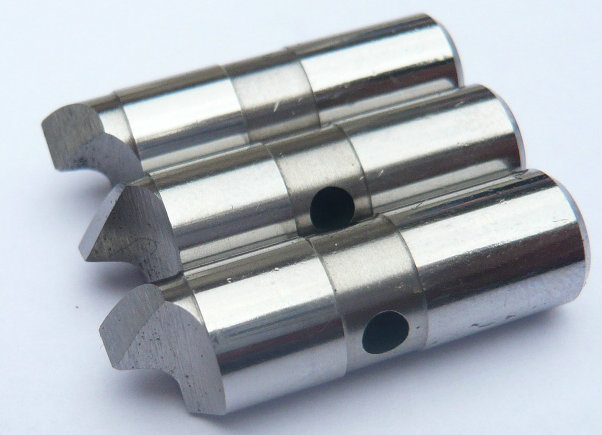

YDTech® manufacturers of custom drive locating pins on face drivers for milling (grinding, lathes) machines ! suppliers of custom drive lock pins for face driver systems on lathes, live (dead) chucks in china.

we only produce drive pins, needle roller pins,custom your drawings or samples, drive pin for torque transmission onto work piece for hard tooling. for higher friction coefficient and higher tool life of drive pin

To replace face driven jaws, no tools or wrenches are required. Simply hold the talons with both hands and let it slide along its axis until it is pulled away from its original position. If necessary, use a rag or pliers for a better grip. When reinstalling the talons, slide them in the direction of the drive shaft with the milled surface facing outward. If the drive has been installed on the machine tool, the operation can also be completed without affecting the accuracy

The degree of wear of the end surface -driven claws is difficult to quantify during or during parts of the parts. Different processing materials and operation coefficients make it difficult for us to understand this information.

Persons who often replace processing types are judged by intuitively observing the blade and the workpiece that just finished the processing, and decided when to repair the claw tongs.

When repairing the blade of the cutting of the side of the surface, the blade of 3 mm was grinded. It is not recommended to make more grinding to ensure that it does not affect the operation of the center. During the grinding process, be careful not to heat the blade

Elastic top driver: To replace the center tip with elastic top -end driving, there is no need for tools or wounds. Just hold the center tip with both hands and let it slide along the axis until it is pulled away from the original position. If necessary, you can use rags or pliers to help to better grasp.

FDP-8 standard of drive pins, mechanical face drivers, lathe face driver driving pins, center points, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.800 | 3.189 | 0.731 | 0.189 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.772 | 0.209 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.811 | 0.228 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.850 | 0.238 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.899 | 0.268 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.929 | 0.288 | FDP 2023 | |||||||

| 0.800 | 3.189 | 0.969 | 0.307 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.008 | 0.327 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.068 | 0.346 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.126 | 0.388 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.008 | 0.327 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.165 | 0.406 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.206 | 0.425 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.265 | 0.446 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.383 | 0.484 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.402 | 0.524 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.441 | 0.543 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.480 | 0.563 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.520 | 0.583 | FDP 2023 | |||||||

| 0.800 | 3.189 | 2.559 | 0.602 | FDP 2023 | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

If the four incisions on the driver are no longer straight, but it is only slightly open, and it should be repaired at this time. In this case, only a few millimeters of grinding a few millimeters. The operator needs to process a large amount of workpieces. Before reaching the above wear, the number of processing workpieces should be marked several times.

When re -loading into the center tip, slide it along the direction of the drive shaft until it reaches the stand. If the driver is already installed on the machine tool, it can also complete the operation without affecting accuracy.

Fixed top driver: In one or two nails with a fixed top -dial driver, one or two nails fix the center tip. Before replacing, loosen the nail, once the center tip is replaced, you need to re -tighten the positioning nail, and pay attention to the milling again along the top

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes