YDTech® manufacturer of drive (driving) pins for CNC face driver centers(chuck, lathe, workholding)! supplier of automatic drive shafts(pins) for CNC mechanical face drive systems in china.

the frequency of maintenance for face drives will depend on several factors, including the type and model of the face driver, the materials being machined, and the frequency of use. In general, face drives should be inspected and maintained on a regular basis to ensure proper operation and to prevent wear and damage.

inspect the face driver pins before each use: check for any signs of wear or damage, such as cracks, chips, or deformation. Make sure that all set screws are tight and that the jaws are clean and free from debris. we only produce drive pins, needle roller pins,precision hardened parts,etc. custom your drawings or samples. not face driver.

replace face drivers parts: If you notice any signs of wear or damage to the face driver, such as worn jaws or a damaged center point, replace the parts as soon as possible to prevent further damage or loss of accuracy. depending on the frequency of use and the type of face driver being used, it may be necessary to schedule regular maintenance or inspection by a qualified technician. This will help ensure that the face driver is operating at peak performance and prevent unexpected downtime due to equipment failure.

the maintenance frequency for face drives will depend on the specific circumstances and conditions of use. It's important to follow the manufacturer's recommendations and guidelines for your specific face driver, and to consult a qualified technician if you have any questions or concerns. the drive pins are "floatingly", thus compensating for variations in work piece, squareness and surface finish. the entire surface of the workpiece can now be finished in one single clamping. we will be glad to design device pins for your work pieces.

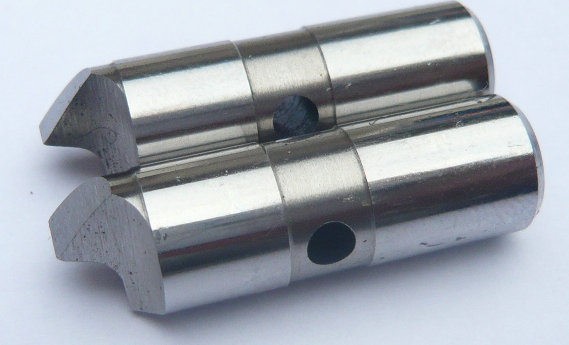

FDT-3 face driver drive pins,workholding, lathe face drivers, drive pins, changeable driving pins, drive teeth pins

| drive pins (quantity) | drive pins (diameter) | face drivers (diameter) | face drivers bodies | screws | center pins | FD technologies | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 6 | 160 | 60 | 3 | 3.5 | FD 2023 | |||||

| 3 | 8 | 160 | 60 | 3 | 3 | FD 2023Z | |||||

| 3 | 6 | 160 | 42 | 3 | 4.25 | FD 2023F | |||||

| 3 | 8 | 160 | 48 | 3 | 6.25 | FD 2023D | |||||

| 3 | 10 | 160 | 70 | 3 | 6.5 | FD 2023D | |||||

| 3 | 10 | 160 | 70 | 3 | 6.5 | FD 2023HG | |||||

| 3 | 15 | 160 | 80 | 3 | 6 | FD 2023FTY | |||||

| 5 | 15 | 160 | 3 | 90 | 12.5 | FD 2023D | |||||

| 5 | 15 | 160 | 3 | 100 | 12.5 | FD 2023GR | |||||

| 5 | 20 | 160 | 3 | 130 | 12.5 | FD 2023RED | |||||

| 5 | 20 | 220 | 3 | 180 | 12.5 | FD 2023IUI | |||||

| 5 | 20 | 250 | 3 | 220 | 12.5 | FD 2023TT | |||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

FDP-3 standard of drive pins,face drivers, lathe face driver driving pins,sizes of drive pins, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.564 | 2.756 | 0.591 | 0.083 | FDPT 2023S | |||||||

| 0.564 | 2.756 | 0.748 | 0.106 | FDPT 2023D | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DD | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DG | |||||||

| 0.564 | 2.756 | 0.827 | 0.146 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.866 | 0.165 | FDPT 2023CV | |||||||

| 0.564 | 2.756 | 0.906 | 0.185 | FDPT 2023FC | |||||||

| 0.564 | 2.756 | 0.946 | 0.205 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.985 | 0.224 | FDPT 2023BNN | |||||||

| 0.564 | 2.756 | 1.025 | 0.244 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.063 | 0.264 | FDPT 2023VV | |||||||

| 0.564 | 2.756 | 1.102 | 0.283 | FDPT 2023F | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VT | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VF | |||||||

| 0.564 | 2.756 | 1.222 | 0.343 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.232 | 0.363 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.417 | 0.441 | FDPT 2023H | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

clean the face driver pins regularly: Remove any debris, coolant, or metal shavings from the face driver after each use. This will help prevent damage to the jaws and ensure that the face driver operates smoothly. lubricate the face driver: apply a suitable lubricant to the face driver and arbor to reduce wear and friction. Be sure to use a lubricant that is compatible with the materials being machined and the type of face driver being used.

face drivers are used on gear processing lathes to hold and rotate a gear or workpiece during the cutting process. They are designed to grip the workpiece by its face, rather than its outer diameter, which allows for more accurate and precise machining. it is important to follow proper safety procedures when using face drivers and other lathe accessories, including wearing appropriate personal protective equipment and adhering to all manufacturer instructions and guidelines.

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes