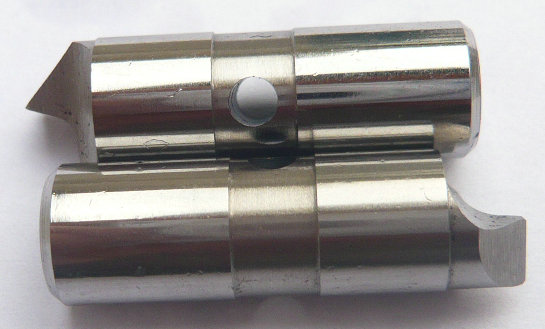

YDTech® manufacturers of drive(blade) pins for face driving on workholding,CNC (milling, drilling, grinding) machines, lathes! suppliers of drive tops as pins for mechanical face drivers or hydraulic face drivers in china.

we only produce drive pins, needle roller pins,custom your drawings not face drivers. Face driver is such a wonderful product for shaft turning. It helps in machining complete shaft in one single setup.This system is more robust and helps in applying great machining parameters.If all is ensured run the machine with the best parameters you can.

So whats the preparation: shaft should be faced and centered. Two type of face drivers available for this application. One driven with the helps of Tail stock thrust. Other one with dual thrust, tail stock and actuating cylinder fitted on the head stock spindle.

In this case component is held between centres and tail stock thrust is applied. The center in Face driver is fixed as such its rigid and the driving disc is connected to actuating cylinders which pushes pins towards face of component for driving. We need to ensure that thrust from head stock should be at least 10% lesser than tail stock thrust, else the tail stock will be pushed backward. For perfect run out of component after machining kindly ensure that their wont be any deflection on the component at the time of thrust actuation

This type of face driver has limitation related to cutting parameters due to less thrust But simple in use and economical. In this case the component is held between centers and thrust is applied to the shaft from tail stock. Face driver on the spindle side will have spring loaded center and floating type driving disc fitted with driving pins which helps in proper biting of pins on to the component face. Float in system helps in any error on the perpendicularity between driving face and center.

FDP-4 standard of drive pins,face drivers, lathe face driver driving pins,sizes of drive pins, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.800 | 4.331 | 3.307 | 0.244 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 3.504 | 0.343 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 3.707 | 0.414 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 3.898 | 0.538 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 4.882 | 0.244 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 5.078 | 0.344 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 5.278 | 0.441 | FDPT 2023 | |||||||

| 0.800 | 4.331 | 5.472 | 0.472 | FDPT 2023 | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

face drive abandons the traditional clamping method, relying on the center center and tailstock center, the center hole is positioned, and the drive claw is inserted into the end face of the workpiece to make the machine tool spindle rotate, so the chuck is abandoned in turning, and the heart clip is abandoned in grinding head, complete the machining of the entire workpiece in one clamping, without turning around.

select the appropriate face driver for your workpiece. The face driver should be chosen based on the size, shape, and weight of the workpiece. mount the face driver onto the lathe spindle. Ensure that it is securely fastened and properly aligned with the lathe axis. insert the workpiece into the face driver and tighten the jaws or clamping mechanism to secure it in place. Be sure to use the appropriate amount of force to avoid damaging the workpiece

- home

- products

- contact

- equipments

- face driver pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- drive pins

- face drives

- drive chuck

- hardened pins

- drive shafts

- center pins

- drive claws

- drive grips

- drive chuck

- driver tops

- locating pins

- driving pins

- cylindrical rollers

- needle rollers

- dowel pins

- capillary tubes