YDTech® manufacturers of cheap mechanical face drivers, lathe chuck centers for grinders, milling machines! suppliers of taper face drivers pins for workholding,gear cutting, turning, grinding in china.

mechanical face drivers are valuable tools in precision machining, offering improved accuracy, reduced vibration, and efficient setup, particularly in turning and grinding operations.

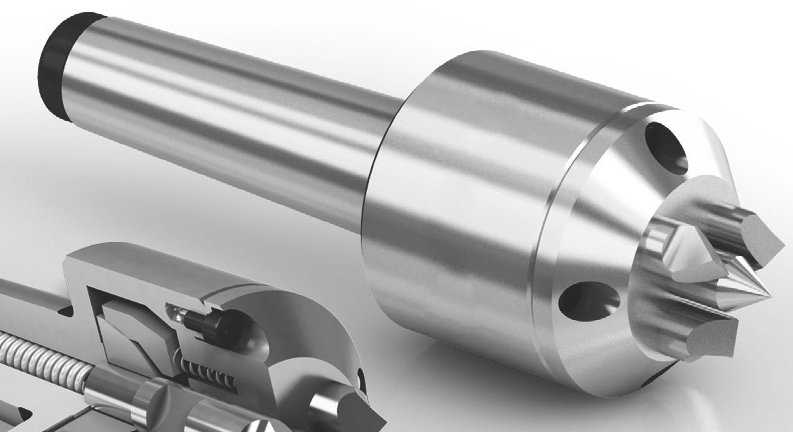

mechanical face drivers are CNC machining center tools used in machining operations, particularly in turning or grinding applications. face drivers are designed to provide a precise and rigid connection between the workpiece and the machine tool, ensuring accurate and efficient machining processes.

the driver head is mounted onto the machine's spindle or tool holder.

the workpiece is placed against the driver head, with the center of the workpiece aligned with the center point of the driver head. as the machine tool rotates, the driver head rotates along with it, maintaining contact with the workpiece. mechanical face drivers are quick change systems

face driver head is the main component that holds the workpiece. It has a face that contacts the workpiece directly.face driver head houses the driver head and is connected to the machine tool.the driver head usually has a center point that aligns with the center of the workpiece.

face drivers help in maintaining concentricity and perpendicularity, ensuring accurate machining. by providing a rigid connection, they reduce vibration, leading to better surface finishes and longer tool life. live face drivers have bearings that allow the driver head to rotate independently of the spindle, reducing wear and tear on the machine. dead face drivers do not have bearings and rely on the machine's spindle rotation.

FDP-8 standard of drive pins, mechanical face drivers, lathe face driver driving pins, center points, changeable driving pins, drive teeth pins

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.800 | 3.189 | 0.731 | 0.189 | FDP 2023SD | |||||||

| 0.800 | 3.189 | 0.772 | 0.209 | FDP 2023EC | |||||||

| 0.800 | 3.189 | 0.811 | 0.228 | FDP 2023DD | |||||||

| 0.800 | 3.189 | 0.850 | 0.238 | FDP 2023FG | |||||||

| 0.800 | 3.189 | 0.899 | 0.268 | FDP 2023CC | |||||||

| 0.800 | 3.189 | 0.929 | 0.288 | FDP 2023GB | |||||||

| 0.800 | 3.189 | 0.969 | 0.307 | FDP 2023CC | |||||||

| 0.800 | 3.189 | 2.008 | 0.327 | FDP 2023DBH | |||||||

| 0.800 | 3.189 | 2.068 | 0.346 | FDP 2023RD | |||||||

| 0.800 | 3.189 | 2.126 | 0.388 | FDP 2023VY | |||||||

| 0.800 | 3.189 | 2.008 | 0.327 | FDP 2023RCV | |||||||

| 0.800 | 3.189 | 2.165 | 0.406 | FDP 2023VF | |||||||

| 0.800 | 3.189 | 2.206 | 0.425 | FDP 2023CG | |||||||

| 0.800 | 3.189 | 2.265 | 0.446 | FDP 2023VV | |||||||

| 0.800 | 3.189 | 2.383 | 0.484 | FDP 2023GU | |||||||

| 0.800 | 3.189 | 2.402 | 0.524 | FDP 2023VU | |||||||

| 0.800 | 3.189 | 2.441 | 0.543 | FDP 2023VJ | |||||||

| 0.800 | 3.189 | 2.480 | 0.563 | FDP 2023HJH | |||||||

| 0.800 | 3.189 | 2.520 | 0.583 | FDP 2023VGJ | |||||||

| 0.800 | 3.189 | 2.559 | 0.602 | FDP 2023B | |||||||

| stainless steel drive pins, face driver CNC drive pins, changeable pins, lathe deep face drivers, face driver technologies | |||||||||||

the typical mechanical face driver requires less tailstock force because 90 to 95 percent of this force is available for the drive pins to bite into the workpiece, with 5 to 10 percent of the tailstock force used to collapse the center pin. in hydraulic face drivers, about 50 percent of the tailstock force is used to collapse the center pin because they have no center pin locking mechanism.

if a manufacturer is producing axles or a similar type of shaft work, it is very important that the dimensions of the part be precise from end to end. however, these dimensions may vary slightly in this type of manufacturing process, as the workpiece may not be perfectly aligned when it is chucked for the second time. both of these problems can be eliminated with the use of a face driver.

- home

- products

- contact

- equipments

- face drivers

- mechanical face drivers

- hydraulic face drivers

- lathe chucks

- tower top face drivers

- live centers

- dead centers

- fixed face drivers

- drill chucks

- CNC tool holders

- custom CNC tools

- drive pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- driving pins