YDTech® manufacturer of live centers,bull nose live centers on CNC lathe (milling, grinding) machines! supplier of lathe dead revolving centers on face drivers for metal lathes tailstocks in china.

live centers, as a revolving centers, is a critical tool used in lathe machines and other machine tools for supporting and rotating a workpiece during machining operations. It is designed to provide support at the non-driven end of the workpiece, reducing deflection and improving accuracy in turning, grinding, and other machining processes. Live centers are essential for ensuring precise and concentric workpiece rotation.

types of live centers:

standard live centers, extended point revolving centers, bull nose live centers, multi use revolving centers etc.

standard live centers: Features a point or cone-shaped center for general-purpose turning. Suitable for a wide range of workpiece materials and applications.

extended point live centers: Has a longer point or nose to reach deeper into the workpiece. Useful for machining long shafts or workpieces with deep holes.

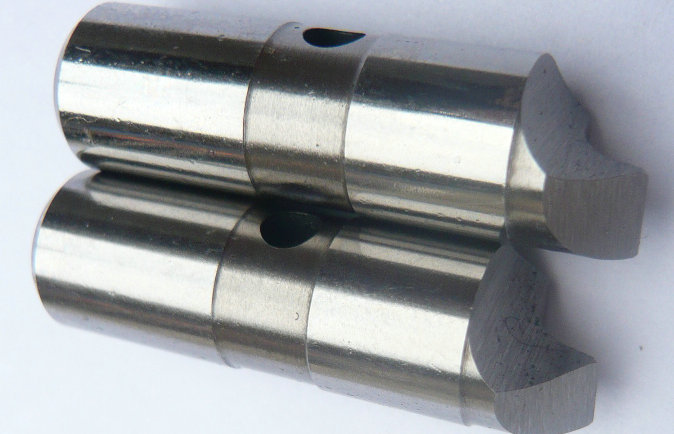

bull nose live centers: Features a larger, flat-end point instead of a cone. Ideal for supporting workpieces with flat surfaces or softer materials.

multi-function live centers:

Includes interchangeable tips for various machining tasks.

Allows for quick customization based on the workpiece requirements.

Applications of Live Centers:

Turning Operations: Used in lathes for turning cylindrical workpieces such as shafts, rods, and bushings. Grinding Operations: Provide support for grinding operations on cylindrical workpieces. Milling Operations: Support workpieces during milling to ensure accurate and stable machining. Metalworking, Woodworking, and Other Machining Processes: Widely used in various industries for a range of machining tasks.

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.197 | 2.441 | 0.591 | 0.083 | FDPT 2023F | |||||||

| 0.197 | 2.441 | 0.630 | 0.102 | FDPT 2023Y | |||||||

| 0.197 | 2.441 | 0.709 | 0.140 | FDPT 2023HH | |||||||

| 0.197 | 2.441 | 0.749 | 0.161 | FDPT 2023TG | |||||||

| 0.197 | 2.441 | 0.787 | 0.188 | FDPT 2023GT | |||||||

| 0.197 | 2.441 | 0.828 | 0.021 | FDPT 2023G | |||||||

| 0.197 | 2.441 | 0.838 | 0.021 | FDPT 2023GUJ | |||||||

| 0.197 | 2.441 | 0.886 | 0.221 | FDPT 2023B | |||||||

| 0.197 | 2.441 | 0.9063 | 0.241 | FDPT 2023 | |||||||

| 0.197 | 2.441 | 0.945 | 0.261 | FDPT 2023H | |||||||

| 0.197 | 2.441 | 0.987 | 0.281 | FDPT 2023R | |||||||

| 0.197 | 2.441 | 1.025 | 0.299 | FDPT 202R3F | |||||||

| 0.197 | 2.441 | 1.063 | 0.318 | FDPT 2023FR | |||||||

| 0.197 | 2.441 | 1.105 | 0.338 | FDPT 2023F | |||||||

| 0.407 | 2.717 | 0.748 | 0.083 | FDPT 2023FJ | |||||||

| 0.407 | 2.717 | 0.787 | 0.102 | FDPT 2023KI | |||||||

| 0.407 | 2.717 | 0.827 | 0.122 | FDPT 2023KI | |||||||

| 0.407 | 2.717 | 0.886 | 0.142 | FDPT 2023K | |||||||

| 0.407 | 2.717 | 0.906 | 0.162 | FDPT 2023BTE | |||||||

| 0.407 | 2.717 | 0.945 | 0.182 | FDPT 2023EH | |||||||

| 0.407 | 2.717 | 0.787 | 0.102 | FDPT 2023E | |||||||

| 0.407 | 2.717 | 0.984 | 0.201 | FDPT 2023GDE | |||||||

| 0.407 | 2.717 | 1.024 | 0.220 | FDPT 2023DEY | |||||||

| 0.407 | 2.717 | 1.068 | 0.240 | FDPT 2023DE | |||||||

| 0.407 | 2.717 | 1.124 | 0.260 | FDPT 2023DR | |||||||

| 0.407 | 2.717 | 1.102 | 0.264 | FDPT 2023DD | |||||||

| 0.407 | 2.717 | 1.042 | 0.281 | FDPT 2023EDTY | |||||||

| 0.407 | 2.717 | 1.260 | 0.339 | FDPT 2023G | |||||||

| live centers, extended point revolving centers, bull nose live centers, multi use revolving centers, lathe face drivers | |||||||||||

Advantages of Live Centers:

Support and Stability: They provide support to the workpiece, reducing the risk of bending or vibration. Improved Surface Finish: By minimizing deflection, they contribute to smoother surface finishes on machined parts. Accuracy and Concentricity: Live centers help maintain precise alignment and concentricity during machining operations. Versatility: Different types of live centers allow for the machining of various materials and workpiece shapes.

live centers are essential components of lathe machines and other machine tools, providing support, stability, and improved accuracy during machining operations. They are crucial for achieving precise and concentric rotation of workpieces, resulting in high-quality machined parts. The choice of live center depends on the specific requirements of the machining task and the characteristics of the workpiece.

- home

- products

- contact

- equipments

- face drivers

- mechanical face drivers

- hydraulic face drivers

- lathe chucks

- tower top face drivers

- live centers

- dead centers

- fixed face drivers

- drill chucks

- CNC tool holders

- custom CNC tools

- drive pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- driving pins