YDTech® manufacturer of collet chucks adapters, live chucks, dead chucks, drills on lathe machines! supplier of three jaw, four jaw & six jaw chucks, independent chucks for metal lathes tailstocks in china.

lathe chucks is a device used to hold and rotate a workpiece securely on a lathe machine during machining operations such as turning, drilling, or milling. Chucks are essential components in metalworking where precise rotation and stability of the workpiece are crucial. They come in various types and sizes to accommodate different workpiece shapes and sizes.

three jaw chucks

Most commonly used for general-purpose work.

Jaws move in unison, allowing for quick setup.

Ideal for holding cylindrical or hexagonal workpieces.

Provides self-centering capabilities.

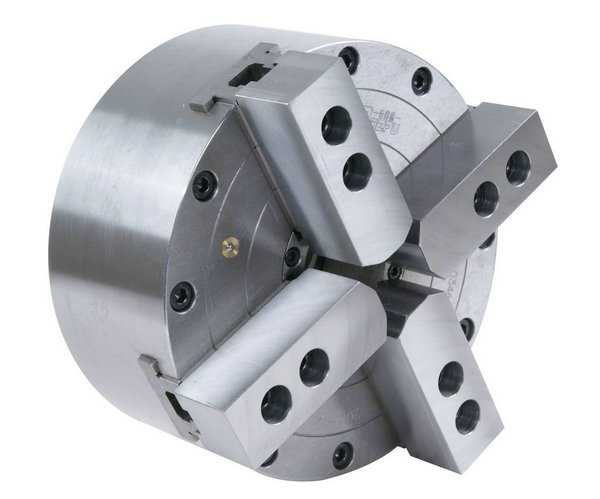

four jaw chucks:

Each jaw can be adjusted independently. Offers more flexibility for holding irregularly shaped workpieces. Useful for off-center or eccentric turning. Requires more time for setup compared to three-jaw chucks.

six jaw chucks:

Provides even more gripping points for improved stability.

Offers superior holding power for thin-walled or delicate workpieces.

Often used for precision machining where concentricity is critical.

collet chucks:

Uses collets to hold the workpiece. Offers high precision and concentricity. Ideal for holding small-diameter workpieces. Commonly used in applications such as watchmaking and electronics.

advantages of lathe chucks:

lathe chucks provide a firm grip on the workpiece, preventing it from moving or slipping during machining.three-jaw chucks, in particular, offer self-centering capabilities, ensuring the workpiece rotates concentrically with the lathe spindle. different types of chucks allow for the machining of a wide range of workpiece shapes and sizes. once the chuck is properly adjusted and mounted, it allows for quick and repeatable setups for subsequent machining operations.

| face drive pins (diameter) | CNC driving pins (length) | lathe drive teeth pins (depth) | driver pin teeths (width) | drive pins technologies | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.564 | 2.756 | 0.591 | 0.083 | FDPT 2023S | |||||||

| 0.564 | 2.756 | 0.748 | 0.106 | FDPT 2023D | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DD | |||||||

| 0.564 | 2.756 | 0.787 | 0.126 | FDPT 2023DG | |||||||

| 0.564 | 2.756 | 0.827 | 0.146 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.866 | 0.165 | FDPT 2023CV | |||||||

| 0.564 | 2.756 | 0.906 | 0.185 | FDPT 2023FC | |||||||

| 0.564 | 2.756 | 0.946 | 0.205 | FDPT 2023C | |||||||

| 0.564 | 2.756 | 0.985 | 0.224 | FDPT 2023BNN | |||||||

| 0.564 | 2.756 | 1.025 | 0.244 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.063 | 0.264 | FDPT 2023VV | |||||||

| 0.564 | 2.756 | 1.102 | 0.283 | FDPT 2023F | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VT | |||||||

| 0.564 | 2.756 | 1.142 | 0.303 | FDPT 2023VF | |||||||

| 0.564 | 2.756 | 1.222 | 0.343 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.232 | 0.363 | FDPT 2023V | |||||||

| 0.564 | 2.756 | 1.417 | 0.441 | FDPT 2023H | |||||||

| three jaw chuck body, four jaw chucks& six jaw chucks, face drivers CNC, changeable pins, lathe deep face drivers, collet chucks | |||||||||||

chuck body: The main housing of the chuck that contains the internal mechanisms. chuck jaws are movable components within the chuck that grip the workpiece. Jaws can be adjusted to hold different sizes of workpieces. gear mechanisms is the mechanism that moves the jaws in and out simultaneously when adjusted. It is often operated by a key or wrench. mounting flange: The part of the chuck that attaches to the lathe spindle. The chuck is often mounted and secured using bolts.

lathe chucks are integral components of lathe machines, providing a means to securely hold and rotate workpieces during various machining processes. they offer versatility, precision, and efficiency in metalworking.

- home

- products

- contact

- equipments

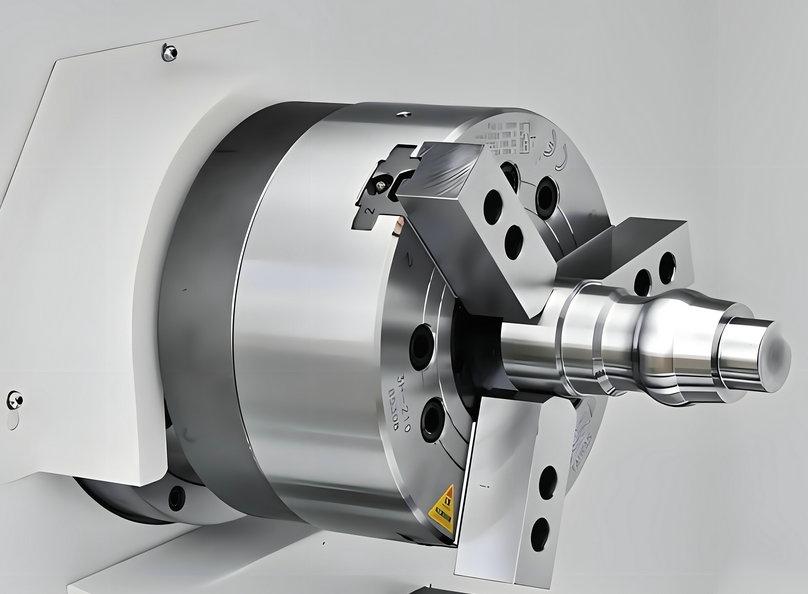

- face drivers

- mechanical face drivers

- hydraulic face drivers

- lathe chucks

- tower top face drivers

- live centers

- dead centers

- fixed face drivers

- drill chucks

- CNC tool holders

- custom CNC tools

- drive pins

- drivers vs pins

- S7 drive pins

- lathe drive pins

- mechanical drive pins

- hardened drive pins

- CNC face drivers

- drive fixture pins

- changeable driving pins

- face driver parts

- driving pins