manufacturers of custom PCD diamond router bits for PTFE, FPC,FR-4, CEM-3, HDI, PCB boards! suppliers of PCd milling bits for phone frame, hard disks,titanium, silicon in china.

PCD ball nose routers for processing the frame border and housing of computer hard disk or cell phone. metals or nonmetals like alluminum, magnesium, titanium and silicon. PCD chamfer tools corner cutting and chamfering. PCD end mills processing the frame border and housing of computer hard disk or cell phone.

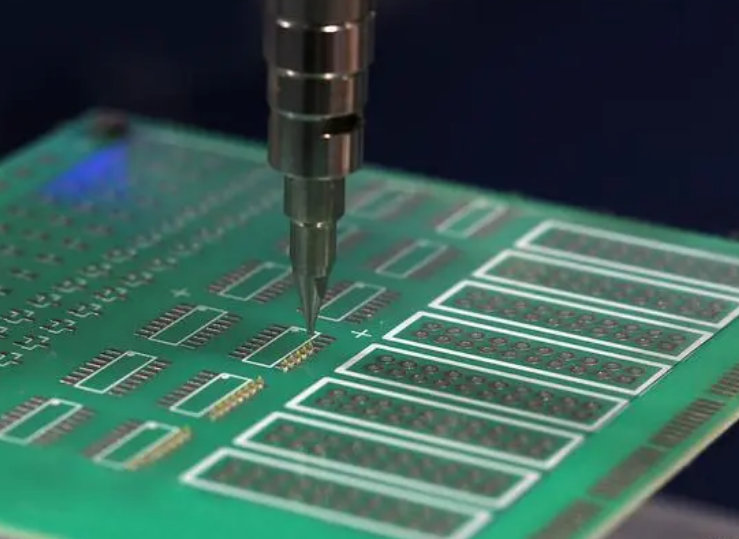

PCD (polycrystalline diamond) end mills are specialized cutting tools used for milling operations on printed circuit boards (PCBs). PCD end mills excel in applications where traditional carbide or high-speed steel tools may wear out quickly due to the abrasive nature of PCB materials. The diamond layer on PCD end mills provides superior wear resistance, resulting in extended tool life and reduced tooling costs.

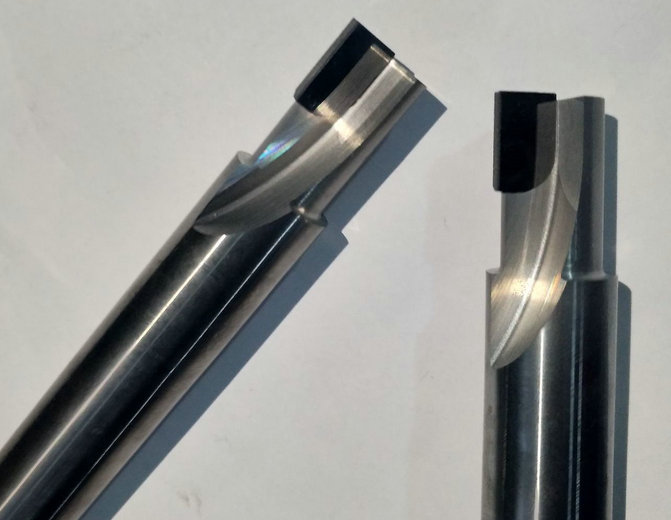

PCD end mills are made from a polycrystalline diamond layer bonded to a carbide substrate. This construction provides exceptional hardness, wear resistance, and thermal conductivity, making them well-suited for machining abrasive materials like fiberglass, epoxy resin, and copper-clad laminates commonly found in PCBs.

PCD end mills are capable of high-speed machining operations due to their excellent heat dissipation properties and low coefficient of friction. This allows for increased cutting speeds and feeds, leading to shorter cycle times and higher productivity. PCD end mills can achieve high levels of precision and surface finish, making them suitable for machining intricate features and fine traces on PCBs. Their sharp cutting edges and minimal edge chipping contribute to the production of precise and clean-cut features.

proper chip evacuation is crucial in PCB machining to prevent chip accumulation and potential damage to the workpiece or cutting tool. PCD end mills are designed with flute geometries optimized for efficient chip evacuation, ensuring smooth machining operations and reducing the risk of tool breakage.

PCD end mills are available in various sizes, geometries, and coatings to suit different PCB machining applications. They can be used in CNC milling machines, engraving machines, and other machining centers commonly employed in PCB fabrication processes.

PCD end mills offer superior performance and longevity compared to conventional cutting tools, their extended tool life and productivity gains often justify the higher initial investment, especially in high-volume production environments.

- home

- products

- contact

- equipments

- PCB micro drill pins

- ST (straight type) drill pins

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins