YDTech® manufacturers of twist carbide drills, PCB micro bits, carbide drill pins & PCB routers, tungsten ST micro drill bits! suppliers of ST series drilling bits, circuit board drill pins, precision CNC twist drills, PCB board router bits in china.

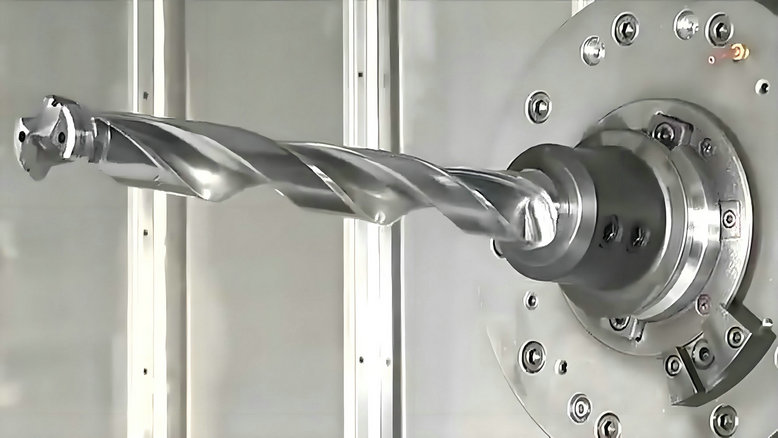

ST (Straight Type) drill bits are a specific type of PCB (Printed Circuit Board) drill bit commonly used in the electronics industry. These drill bits have a straight shank design, meaning that the shank of the drill bit is cylindrical and does not taper. The straight shank allows for easy insertion into and removal from a drill chuck.

PCB micro drill bits are classified according to the shape of the front end. The ST type is an ordinary drill bit with a straight busbar in the drill body. ST drill bits are preferred for their stability and ease of use, especially when drilling precise holes in PCBs. The straight shank design provides better alignment and reduces the likelihood of wobbling or drifting during drilling, which is crucial for maintaining accuracy in PCB fabrication.

In contrast, other types of PCB drill bits, such as those with tapered shanks or specialized shank designs, may have specific applications or advantages in certain situations. However, ST drill bits are widely used and considered a standard choice for general-purpose PCB drilling tasks.

twist micro carbide PCB drill bits are a universal drill bit which can be used for many materials and industries. the twist micro carbide PCB drill bitsare also used for small through holes, blind via hole drilling or via inter connectors, they allow forimproved inner hole wall quality, whilst maintaining good registration accuracy. this makes them ideal for high density multilayer circuit boards.

carbide micro-drill bits are commonly used for drilling small-diameter holes in PCBs, typically ranging from around 0.05 mm to 1.0 mm in diameter. These drill bits are made from carbide, which provides excellent hardness and wear resistance, making them suitable for drilling through tough PCB materials like fiberglass and epoxy resin.

drill bit for drilling holes in a PCB (Printed Circuit Board) depends on several factors, including the size of the holes, the type of material being drilled, and the specific requirements of the PCB design.

| type | Series | Diameter | Features | ||||||||

| ST | SA | Φ 0.075 ~ Φ 0.350 mm | Excellent Hole Accuracy | ||||||||

| ST | SH | Φ 0.075 ~ Φ 0.350 mm | Excellent Hole Wall Quality | ||||||||

| ST | SHA | Φ 0.075 ~ Φ 0.350mm | Balance of hole accuracy & hole wall quality | ||||||||

| ST | ST | Φ 0.300 ~ Φ 3.175mm | General Purpose | ||||||||

| PCB twist drills, carbide pin drills, PCB drill bits,PCB router bits, CNC drill pins,PCB milling cutters, circuit board drill bits,circuit board slot drills, cemented carbide mini drills, PCB tungsten pins. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

sizes of standard cemented carbide micro drill pins shank <3.175mm for PCB (printed circuit boards)

diamond-coated drill bits are used for drilling through abrasive materials like ceramic-filled PCB substrates or materials with hard metal coatings. The diamond coating provides exceptional hardness and wear resistance, allowing for extended tool life and precise drilling performance.

| drill diameter, | drill length | drill diameter, | drill length | drill diameter, | drill length | ||||||

| 0.05, | 0.60, | 1.05, | 10.50, | 2.15, | 10.50 | ||||||

| 0.08, | 0.80, | 1.10, | 10.50, | 2.20, | 10.50 | ||||||

| 0.10, | 1.20, | 1.15, | 10.50, | 2.25, | 10.50 | ||||||

| 0.12, | 2.00, | 1.20, | 10.50, | 2.30,1 | 0.50 | ||||||

| 0.15 | ,2.00, | 1.25, | 10.50, | 2.35, | 10.50 | ||||||

| 0.20, | 3.50, | 1.30, | 10.50, | 2.40, | 10.50 | ||||||

| 0.25, | 4.00, | 1.35, | 10.50, | 2.45, | 10.50 | ||||||

| 0.30, | 5.50, | 1.40, | 10.50, | 2.50, | 10.50 | ||||||

| 0.35, | 5.50, | 1.45, | 10.50, | 2.22, | 10.50 | ||||||

| 0.40, | 7.00, | 1.50, | 10.50, | 2.60, | 10.50 | ||||||

| 0.45, | 7.00, | 1.55, | 10.50, | 2.65, | 10.50 | ||||||

| 0.50, | 8.50, | 1.60, | 10.50, | 2.70, | 10.50 | ||||||

| 0.55, | 8.50, | 1.65, | 10.50, | 2.75, | 10.50 | ||||||

| 0.60, | 9.50, | 1.70, | 10.50, | 2.80, | 10.50 | ||||||

| 0.65, | 9.50, | 1.75, | 10.50 | 2.85, | 10.50 | ||||||

| 0.70, | 9.50, | 1.80, | 10.50 | ,2.90, | 10.50 | ||||||

| 0.75, | 9.50, | 1.85, | 10.50, | 2.95, | 10.50 | ||||||

| 0.80, | 9.50, | 1.90, | 10.50, | 3.00, | 10.50 | ||||||

| 0.85, | 9.50, | 1.95, | 10.50, | 3.05, | 10.50 | ||||||

| 0.90, | 9.50, | 2.00, | 10.50, | 3.10, | 10.50 | ||||||

| 0.95, | 9.50, | 2.05, | 10.50, | 3.15, | 10.50 | ||||||

| 1.00, | 10.50, | 2.10, | 10.50, | 3.175, | 10.50 | ||||||

| custom PCB drill bits,PCB router bits, microtwist bits, CNC drill pins,PCB milling cutters, circuit board drill bits,circuit board slot drills, cemented carbide mini drills, PCB tungsten pins | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

high speed steel drill bits are another option for drilling PCBs, especially for larger hole sizes or when drilling through softer materials. HSS drill bits are more affordable than carbide bits and are suitable for drilling holes with diameters larger than 1.0 mm.

PCB router bits are used for cutting larger holes or creating special features on PCBs, such as slots, notches, or irregular shapes. These router bits typically have flat or ball-shaped cutting profiles and are mounted on CNC (Computer Numerical Control) milling machines for precise machining operations.

selecting a drill bit for PCB drilling, it's essential to consider the specific requirements of the PCB design, including hole size, material type, and tolerance specifications. Additionally, proper tool maintenance and handling are crucial for maximizing the performance and longevity of the drill bits.

- home

- products

- contact

- equipments

- PCB micro drill pins

- ST (straight type) drill pins

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins