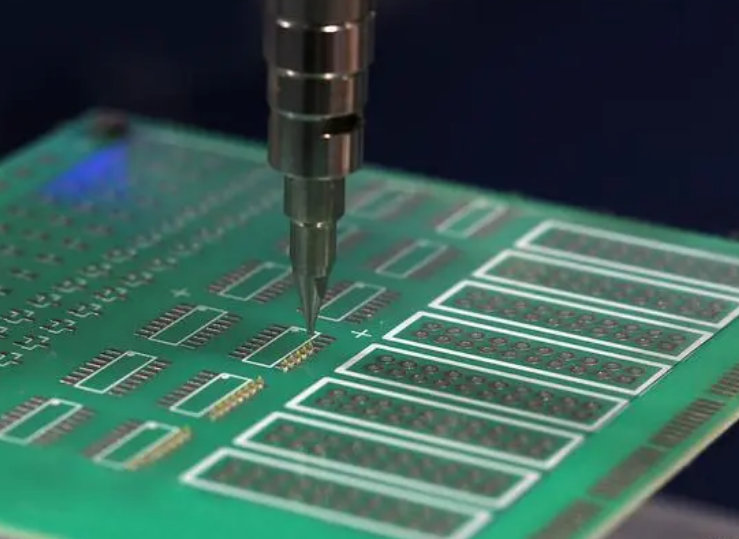

manufacturers of custom carbide PCB cutting tools for PCB(printed circuit board) drilling, grooving, milling, cutting! suppliers of PCB 1,2,3 flute router bits for packaging substrate,copper board, PTFE, FPC,FR-4, CEM-3, HDI, PCB boards in china!

PCB groove knives, as V-groove knives or V-scoring blades, are specialized cutting tools used in the fabrication of printed circuit boards (PCBs). These knives are designed to create V-grooves or score lines in the PCB substrate, which facilitate the separation of individual PCBs from a larger panel after manufacturing.

radius end mills,it is flat bottom end mill for processing arc surface in the slot, suitable for arc surface chamfering of PCBs, copper-base boards.

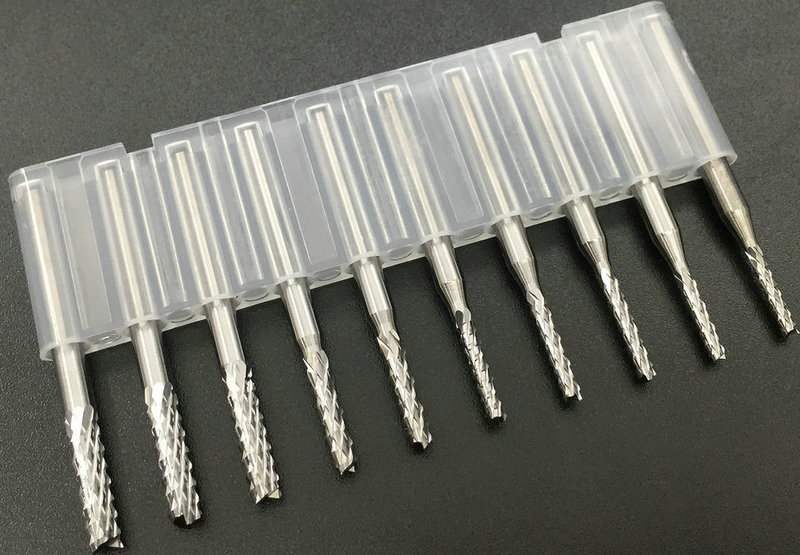

two flute end mills, it is a flat end mill for processing bevel in the slot, suitable for processing bevel in the flat slot of copper-base board, PCBs and etc.

single edge inclined-flute chamfer tool,suitable for beveling, chamfering and V-groove routing of PCBs.

single-edge straight-flute chamfer tool, suitable for beveling and chamfering of PCBs and V-groove routing and figure engraving of acrylic boards.

bevel cutter for terminal beveling machine with multiple cutting edges whose shank length can be customized.

multiple-edge chamfer tool for processing countersink. processing and suitable to chamfer pale edges, copper base board and PCBs.

single-edged endmill with sharp cutting edge and large chip pocket; for cut-off processing of soft boards that easily appear burr problems,such as PTFE and etc

PCB groove knives are typically mounted on a cutting machine, such as a CNC (Computer Numerical Control) router or a V-groove cutting machine. These knives feature sharp blades with a V-shaped profile, which are used to cut grooves or score lines into the surface of the PCB substrate.

PCBs are often manufactured in panel form, where multiple individual boards are interconnected within a larger panel. The grooves created by PCB groove knives define the boundaries between individual PCBs on the panel, allowing for efficient assembly and handling during the manufacturing process.

after the PCBs are assembled and soldered, they are separated from the larger panel using a score-and-break method. This involves applying pressure along the scored lines created by the PCB groove knives, which causes the PCBs to break cleanly along the grooves, separating them from the panel without damaging the circuitry or components.

custom fixed shank 2 flute end mills for PCB boards, copper base boards, flat slot.

| blade diameter | blade length | shank diameter | total length | number blades | |||||||

| 0.40 | 2.00 | 3.175 | 38.1 | 2 | |||||||

| 0.50 | 2.50 | 3.175 | 38.1 | 2 | |||||||

| 0.60 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 0.70 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 0.80 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 0.90 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.00 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.10 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.20 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.30 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.40 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.50 | 3.00 | 3.175 | 38.1 | 2 | |||||||

| 1.60 | 4.00 | 3.175 | 38.1 | 2 | |||||||

| 1.70 | 4.00 | 3.175 | 38.1 | 2 | |||||||

| 1.80 | 4.00 | 3.175 | 38.1 | 2 | |||||||

| 1.90 | 4.00 | 3.175 | 38.1 | 2 | |||||||

| 2.00 | 4.00 | 3.175 | 38.1 | 2 | |||||||

| 2.10 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.20 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.30 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.40 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.50 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.60 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.70 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.80 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 2.90 | 5.00 | 3.175 | 38.1 | 2 | |||||||

| 3.00 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.10 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.175 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.20 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.30 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.40 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.50 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.60 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.70 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.80 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 3.90 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| 4.00 | 6.00 | 3.175 | 38.1 | 2 | |||||||

| tungsten router bits, PCB milling cutters, carbide routers, PCB end mills,circuit board drill bits, router bits, carbide mini drills, slotting drills, chamfering mills, slotting drills, spiral mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| drills bits | |||||||||||

| excellent hole wall quality, | UHQ | ||||||||||

| FPC, | A129FP | ||||||||||

| metal base boards | G129MB | ||||||||||

| high multi layer boards, | USF | ||||||||||

| router bits | |||||||||||

| general PCBs, | 171RN | ||||||||||

| long life type, | C5TR,151RH | ||||||||||

| excellent routing quality, | 141HFR | ||||||||||

| FPC/PTFE, | 161R,111R | ||||||||||

| metal base boards, | 162RA,163R,162R | ||||||||||

| custom PCB drill bits,PCB router bits, microtwist bits, CNC drill pins,PCB milling cutters, circuit board drill bits,circuit board slot drills, carbide mini drills, PCB tungsten drill pins | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

single edge straight flute chamfer tools for V-groove routing, figure engraving on copper board, aluminum board,PCBs.

| d | D | L | ω | Z | |||||||

| 3.175 | 3.175 | 38.1 | 30° | 1 | |||||||

| 3.175 | 3.175 | 38.1 | 60° | 1 | |||||||

| 3.175 | 3.175 | 38.1 | 90° | 1 | |||||||

| 3.175 | 3.175 | 38.1 | 120° | 1 | |||||||

| 3.175 | 3.175 | 38.1 | 140° | 1 | |||||||

| tungsten router bits, PCB milling cutters, carbide routers, PCB end mills,circuit board drill bits, router bits, carbide mini drills, slotting drills, chamfering mills, slotting drills, spiral mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

single-edge inclined-flute chamfer tools for V-groove routing, beveling taper hole(central hole) on copper board, aluminum board, PCBs.

| Blade diameter, | Blade length, | Handle diameter, | Length, | Number blades | Blade angle, | ||||||

| 2.00 | 5.0 | 3.175 | 38.1, | 2 | 30°60°82°90°100°120°140°° | ||||||

| 3.00 | 6.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| 3.175 | 7.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| 4.00 | 13.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| 5.00 | 13.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| 6.00 | 13.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| 6.35 | 13.0 | 3.175 | 38.1, | 2 | 60°82°90°100°120°140° | ||||||

| tungsten router bits, PCB milling cutters, carbide routers, PCB end mills,circuit board drill bits, router bits, carbide mini drills, slotting drills, chamfering mills, slotting drills, spiral mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- PCB micro drill pins

- ST (straight type) drill pins

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins