YDTech® manufacturers of SD type slotting drills, PCB micro slot bits, carbide slot end mills & PCB routers, tungsten SD micro drill bits! suppliers of SD series drilling grooved bits, circuit board slotting cutters, precision CNC twist drills, PCB board router bits in china.

PCB slot drills, as slotting cutters or slot end mills, are specialized cutting tools used in the fabrication of printed circuit boards (PCBs). These drills are designed to create slots or channels in PCB substrates to accommodate electronic components or to separate different sections of the PCB.

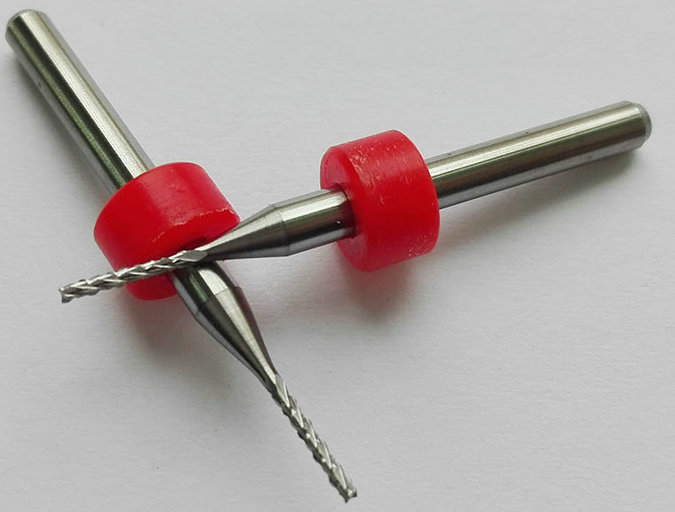

PCB micro drill bits are classified according to their uses, including SD-type drill bits and conventional drill bits. SD-type drill bits: slot drills used for processing narrow grooves, slotting, and conventional drilling drills.

PCB slot drills are specifically designed to cut slots or channels into PCB substrates with precision and accuracy. These slots may be used for various purposes, such as mounting components, creating connectors, or dividing different sections of the PCB.

PCB micro drill bits are classified according to their uses, including SD-type drill bits and conventional drill bits. SD-type drill bits: slot drills used for processing narrow grooves, slotting, and conventional drilling drills.

slotting cutters for PCBs are engineered to provide precise and clean cuts, ensuring that the slots are accurately sized and positioned according to design specifications. This precision is essential for proper component placement and electrical connectivity within the PCB.

PCB slot end mills are suitable for cutting through a wide range of PCB materials, including fiberglass, epoxy resin, copper-clad laminates, and other substrates commonly used in PCB fabrication. They are designed to withstand the abrasive nature of these materials and maintain sharp cutting edges for extended periods of use.

Slot drills for PCBs come in various sizes and configurations to accommodate different slotting requirements. They can be used for creating slots of different widths, depths, and lengths to meet the specific needs of PCB designs.

Efficient chip evacuation is important during slotting operations to prevent chip buildup, which can lead to tool damage and surface defects. PCB slot drills often feature specialized flute designs or coatings to facilitate chip evacuation and improve cutting performance.

PCB slot drills contribute to achieving smooth and burr-free slot edges, which is crucial for ensuring proper component insertion and electrical connectivity. High-quality slot drills with sharp cutting edges and precise geometries minimize surface roughness and burrs, resulting in clean slots with excellent surface finish.

PCB slot drills are essential tools in the PCB manufacturing process, enabling precise and efficient slotting operations to create slots or channels for various electronic components and features on PCBs. Their precision, versatility, and compatibility with different PCB materials make them indispensable for producing high-quality PCBs for electronic applications.

- home

- products

- contact

- equipments

- PCB micro drill pins

- ST (straight type) drill pins

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins