manufacturers of carbide spiral flute end mills for metal boards,plastic,communication boards,PTFE, FPC,HDI,5G metal boards! suppliers of PCB spiral type mill blades, PCB drill bits, carbide milling cutters,tungsten routers and end mills for PCB in china.

PCB spiral mill blades, as spiral flute end mills or spiral router bits, are specialized cutting tools used in the fabrication of printed circuit boards (PCBs). These blades feature a spiral-shaped flute design along their cutting edges, which distinguishes them from traditional straight-flute end mills.

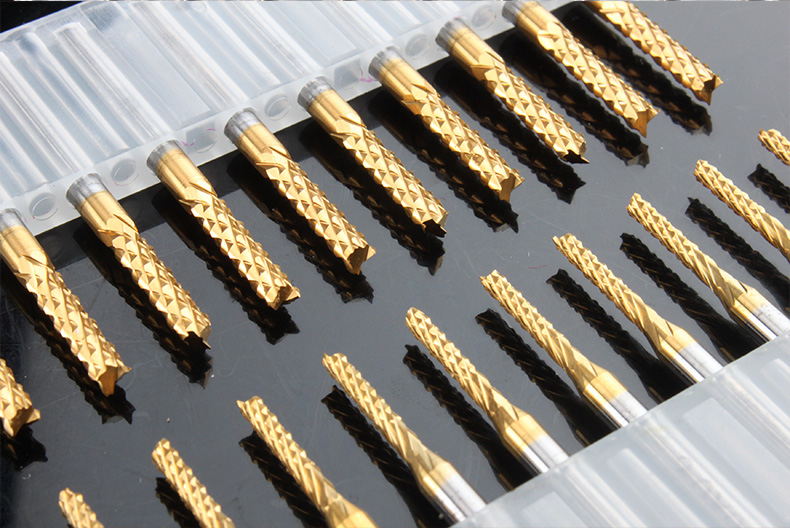

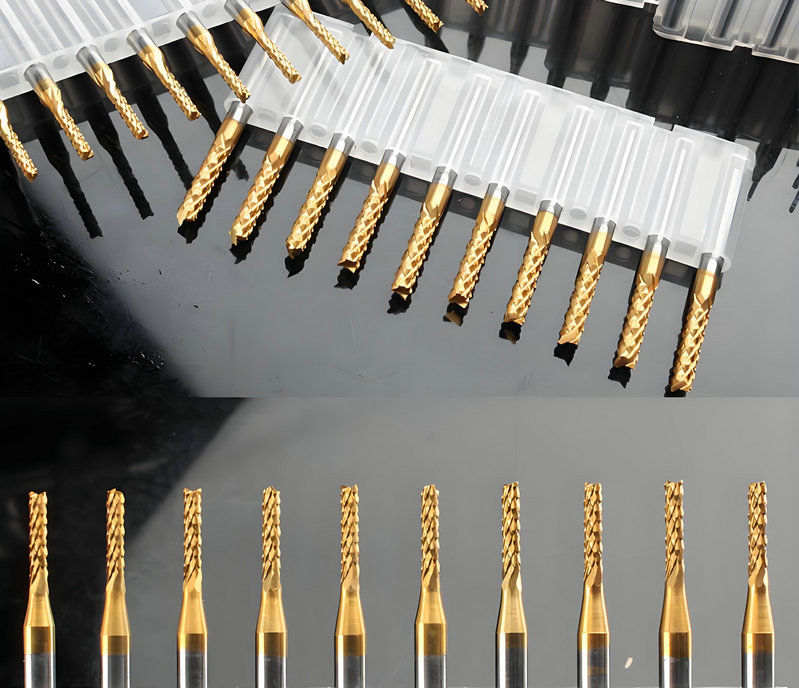

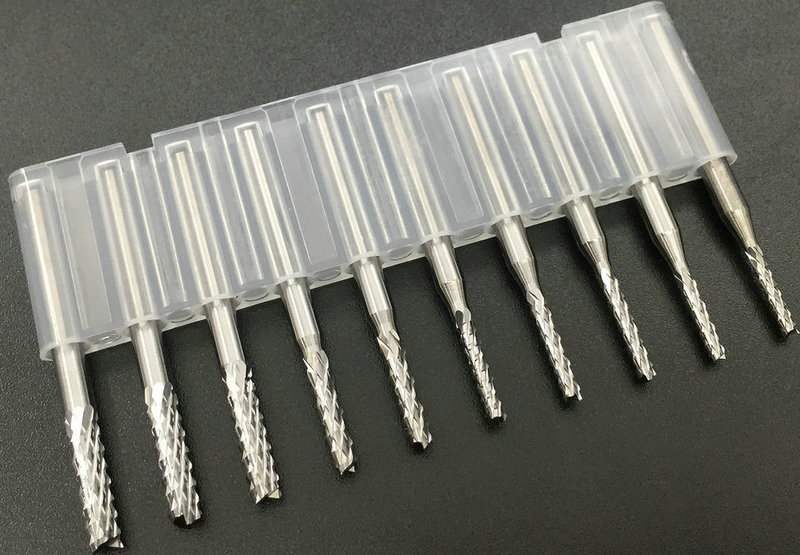

The spiral milling cutter is a milling cutter without chip grooves on the blade. The spiral milling cutter processes printed circuit boards with high quality requirements, such as: flexible copper-clad laminates, metal substrates, and polytetrafluoroethylene boards.

the spiral flute design of these blades helps facilitate efficient chip evacuation during the milling process. As the blades cut through the PCB material, the spiral flutes help to channel chips away from the cutting area, preventing chip buildup and reducing the risk of tool damage or surface defects.

the spiral flute design of these blades helps facilitate efficient chip evacuation during the milling process. As the blades cut through the PCB material, the spiral flutes help to channel chips away from the cutting area, preventing chip buildup and reducing the risk of tool damage or surface defects.

the spiral flute geometry allows for smoother cutting action and more efficient material removal compared to straight-flute end mills. This can result in faster machining speeds, reduced cutting forces, and improved overall cutting performance.

PCB spiral flute end mills can contribute to achieving better surface finishes on PCBs due to their smoother cutting action and chip evacuation capabilities. This is particularly important in PCB fabrication, where surface quality is critical for ensuring proper electrical performance and component placement.

| 3 | 8 | 160 | 70 | 3 | 6.25 | FD 2023 | |||||

| 3 | 10 | 160 | 70 | 3 | 6.5 | FD 2023Z | |||||

| 3 | 10 | 160 | 70 | 3 | 8.5 | FD 2023F | |||||

| 5 | 15 | 160 | 90 | 3 | 12.5 | FD 2023D | |||||

| 5 | 15 | 160 | 100 | 3 | 12.5 | FD 2023GR | |||||

| 5 | 20 | 160 | 132 | 3 | 12.5 | FD 2023RED | |||||

| tungsten router bits, PCB milling cutters, carbide routers, PCB end mills,circuit board drill bits, router bits, carbide mini drills, slotting drills, chamfering mills, slotting drills, spiral mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- PCB micro drill pins

- ST (straight type) drill pins

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins