manufacturers of carbide high speed end mills,back drills,countersunk drills, spiral mills, graver for PTFE, FPC,HDI,5G metal boards! suppliers of PCB Flat bottom milling cutters, high speed UC(under cut) drill bits, PCBtungsten routers and end mills for PCB in chin

high speed drills for printed circuit boards (PCBs) are essential for precise and efficient drilling of holes in PCBs, particularly when working with high-density boards or boards with small components.

invest in high-speed drill machines designed specifically for PCB drilling. These machines typically have high spindle speeds and precise control mechanisms to ensure accuracy and consistency. high rigidity, good chip evacuation and excellent hole registration accuracy.

can ensure excellent hole registration accuracy and improve processing eifficency.

pay attention to the geometry of the drill bits. Point angles, flute designs, and edge geometries can affect the drilling process, especially when dealing with different materials and board thicknesses. optimize feed rates and spindle speeds based on the material being drilled and the diameter of the drill bits. High-speed drilling requires balancing between cutting speed and feed rate to prevent overheating and ensure chip evacuation.

implement effective cooling and lubrication systems to dissipate heat generated during drilling. this can help prevent tool wear, prolong tool life, and improve hole quality. use software tools to optimize the drill path, minimizing travel distances and reducing drilling time. This is particularly important for high-volume production runs.

regularly inspect drill bits for signs of wear or damage, and replace them as needed. Proper maintenance of drill machines and tooling is crucial for consistent performance.

different PCB materials have varying hardness and thermal properties, which can affect the drilling process. Adjust drilling parameters accordingly when working with materials like FR-4, aluminum-backed boards, or ceramic substrates.

ensure precise control over drilling depth and hole placement to meet design specifications and avoid damaging sensitive components or traces on the PCB. implement quality assurance measures throughout the drilling process, including post-drilling inspections and testing to verify hole size, position, and quality.

sizes of high speed drill bits UC(under cut) type for PCB (printed circuit boards)

| Dmm | 0.30 | 0.35 | 0.40 | 0.45 | 0.50 | 0.55 | 0.60 | ||||

| Lmm | 5.00 | 5.00 | 5.00 | 5.00 | 5.50 | 5.50 | 5.50 | ||||

| Dmm | 0.65 | 0.70 | 0.75 | 0.80 | 0.85 | 0.90 | 0.95 | ||||

| Lmm | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | ||||

| Dmm | 1.00 | 1.05 | 1.10 | 1.15 | 1.20 | 1.25 | 1.30 | ||||

| Lmm | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | ||||

| Dmm | 1.35 | 1.40 | 1.45 | 1.50 | 1.55 | 1.60 | 1.65 | ||||

| Lmm | 5.50 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | ||||

| Dmm | 1.70 | 1.75 | 1.80 | 1.85 | 1.90 | 1.95 | 2.00 | ||||

| Lmm | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | ||||

| tungsten router bits, PCB milling cutters, carbide routers, PCB end mills,circuit board drill bits, router bits, carbide mini drills, slotting drills, chamfering mills, slotting drills, spiral mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| drills bits | |||||||||||

| excellent hole wall quality, | UHQ | ||||||||||

| FPC, | A129FP | ||||||||||

| metal base boards | G129MB | ||||||||||

| high multi layer boards, | USF | ||||||||||

| router bits | |||||||||||

| general PCBs, | 171RN | ||||||||||

| long life type, | C5TR,151RH | ||||||||||

| excellent routing quality, | 141HFR | ||||||||||

| FPC/PTFE, | 161R,111R | ||||||||||

| metal base boards, | 162RA,163R,162R | ||||||||||

| custom PCB drill bits,PCB router bits, microtwist bits, CNC drill pins,PCB milling cutters, circuit board drill bits,circuit board slot drills, carbide mini drills, PCB tungsten drill pins | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

- home

- products

- contact

- equipments

- PCB micro drill pins

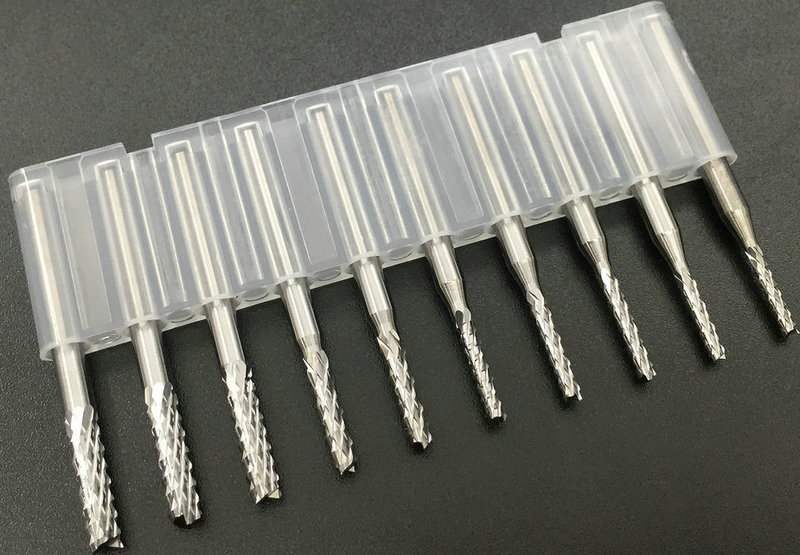

- ST (straight type) drill pins

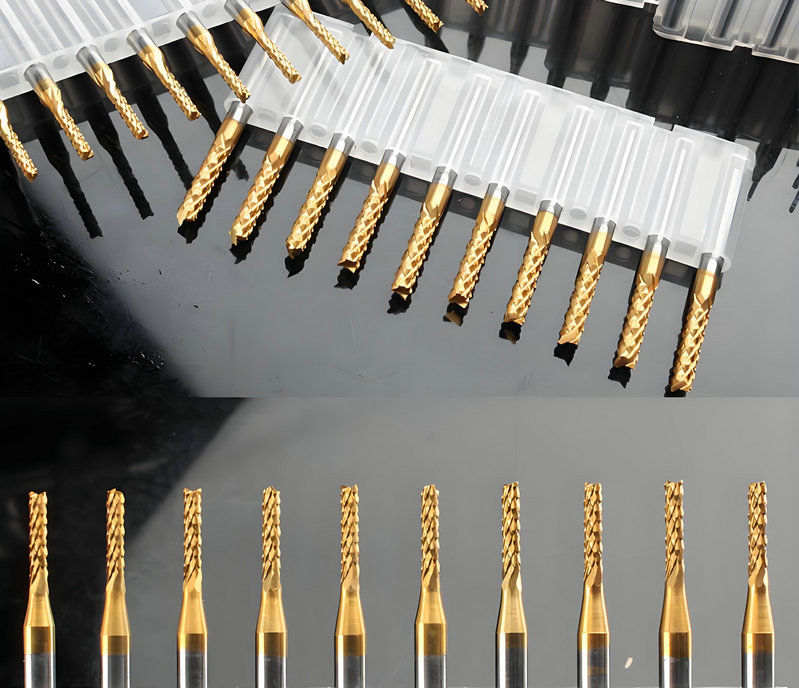

- UC(under cut)miniature drills

- ID (inverse drill) pins

- SD slot drills

- HD high speed drills

- PCB router end mills

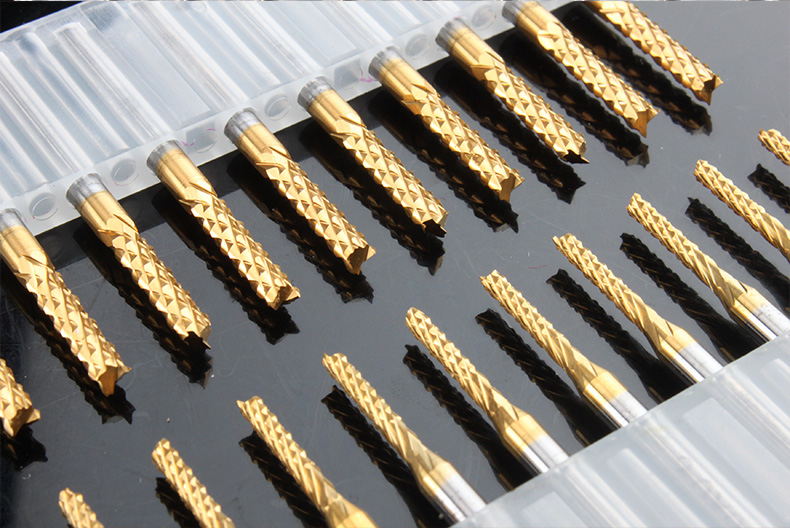

- DC(diamond cut)corn tooth routers

- CB(chip breaker) end mills

- PCB spiral milling bits

- custom PCB milling cutters

- superhard PCD tools

- CNC drill bits

- CNC tool holders

- face drivers

- drive pins